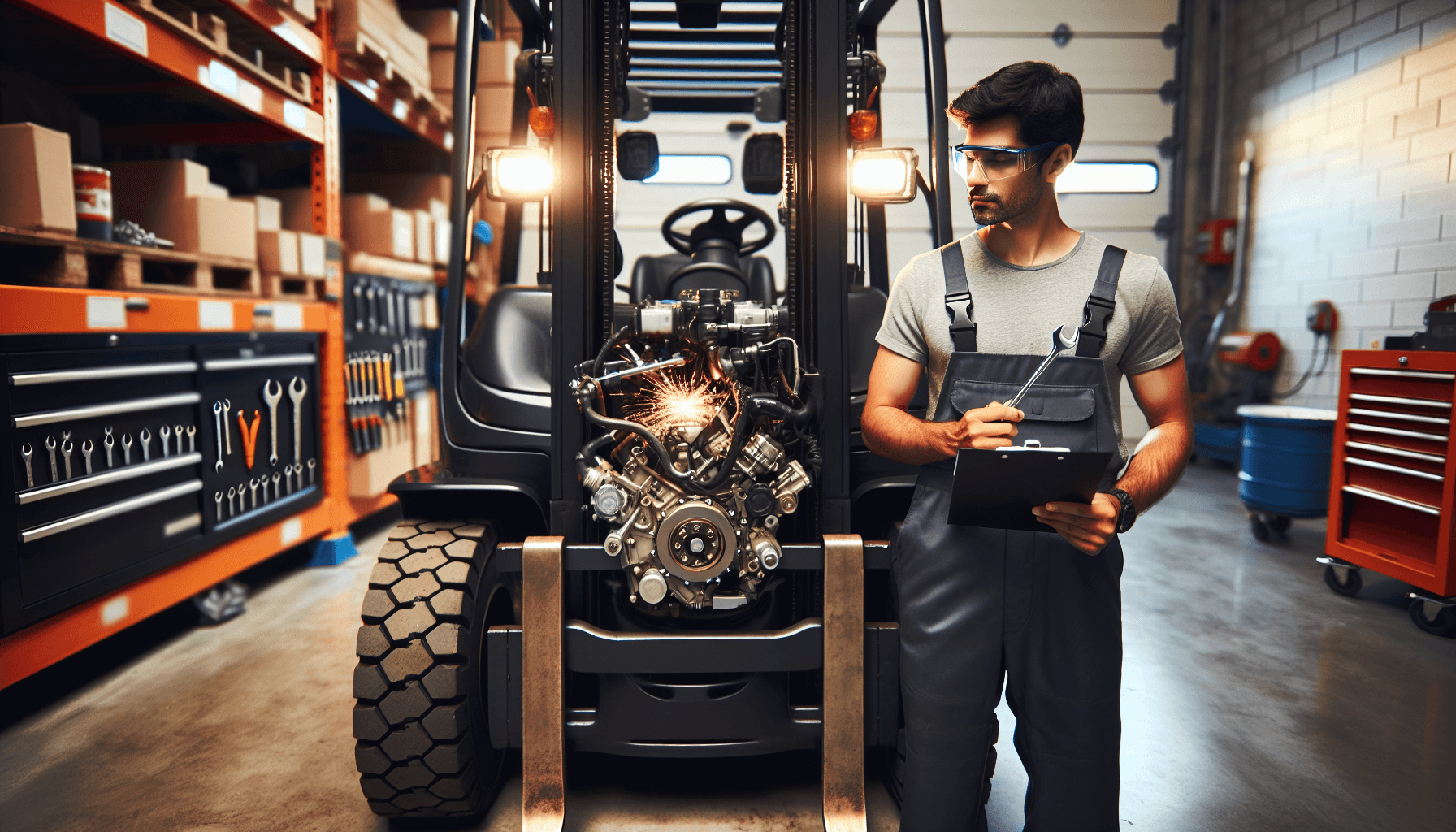

Proper maintenance of forklift engines is essential for ensuring optimal performance and longevity of these vital warehouse tools. Forklifts are a crucial part of warehouse operations, helping to transport heavy loads efficiently and effectively. As such, it is important to prioritize regular maintenance of forklift engines to minimize downtime, improve productivity, and enhance safety within the warehouse.

The Cost of Neglecting Forklift Engine Maintenance

Neglecting regular maintenance of forklift engines can lead to a range of problems that can impact both productivity and profitability. Here are some of the costs associated with not properly maintaining the engines:

- Increased repair costs: Ignoring routine maintenance can result in more frequent breakdowns and expensive repairs. Components such as filters, belts, and fluids need regular inspections and replacements to prevent major malfunctions.

- Reduced lifespan: Lack of maintenance can significantly reduce the lifespan of a forklift engine. Regular servicing, including oil changes and tune-ups, helps to extend the lifespan of the engine and increase its durability.

- Downtime: When a forklift breaks down unexpectedly due to poor maintenance, it can disrupt warehouse operations and cause delays in shipments. Downtime can lead to lost productivity and missed deadlines, impacting the overall efficiency of the warehouse.

- Safety hazards: Neglected forklift engines can pose serious safety risks to operators and other warehouse personnel. Engine malfunctions can lead to accidents and injuries that could have been preventable with proper maintenance. Ensuring the forklift engine is in good working condition reduces the chances of accidents in the warehouse.

- Decreased fuel efficiency: Regular maintenance, including cleaning or replacing air filters and tuning the engine, helps to optimize fuel efficiency. A properly maintained engine consumes less fuel, reducing operating costs in the long run.

Given the potential costs and risks associated with neglecting forklift engine maintenance, it is crucial for warehouses to implement a proactive maintenance program. This program should include the following key elements:

Regular Inspections

Regular inspections are necessary to identify any potential issues before they become major problems. This includes checking fluid levels, inspecting belts and hoses, and examining the overall condition of the engine. technicians can carefully inspect the engine for any signs of wear and tear or potential mechanical issues. They can also identify and address any leaks or abnormal noises that may be indicators of underlying problems.

Fluid Changes and Replacements

Regular fluid changes and replacements are essential for optimal engine performance. This includes changing the engine oil, coolant, hydraulic fluid, and other necessary fluids. Clean fluids help lubricate moving parts, reduce friction, and prevent overheating. Regular fluid replacements ensure that the engine is always operating with clean and properly functioning fluids.

Filter Cleaning and Replacements

Filters, such as air filters and fuel filters, play a crucial role in preventing contaminants from entering the engine and causing damage. Regularly cleaning or replacing filters helps maintain optimal air and fuel flow, improving combustion and reducing engine stress. This ultimately leads to better engine performance and efficiency.

Tune-ups and Adjustments

Regular tune-ups and adjustments are necessary to keep the engine running at its best. This includes checking and adjusting spark plug gaps, ignition timing, and valve clearances. Technicians can also identify and address any issues with the fuel injection system or the engine’s electronic components.

Choosing the Right Partner for Forklift Engine Maintenance

Proper forklift engine maintenance requires knowledge, expertise, and experience. It is essential to partner with a reliable and reputable provider of turnkey forklift maintenance solutions like HCO Innovations. HCO Innovations specializes in optimizing warehouse operations, including forklift engine maintenance. Their team of skilled technicians is experienced in diagnosing and maintaining forklift engines to ensure optimal performance and longevity.

With HCO Innovations, warehouses can benefit from regular inspections, fluid changes and replacements, filter cleaning and replacements, and tune-ups and adjustments. Their services can help warehouses minimize downtime, improve productivity, enhance safety, and ultimately reduce overall maintenance costs.

Don’t wait for engine problems to arise. Contact HCO Innovations today for comprehensive forklift engine maintenance solutions. Together, we can optimize your warehouse operations and ensure the longevity and performance of your forklift engines.

Visit HCO Innovations to learn more about their turnkey forklift maintenance solutions.