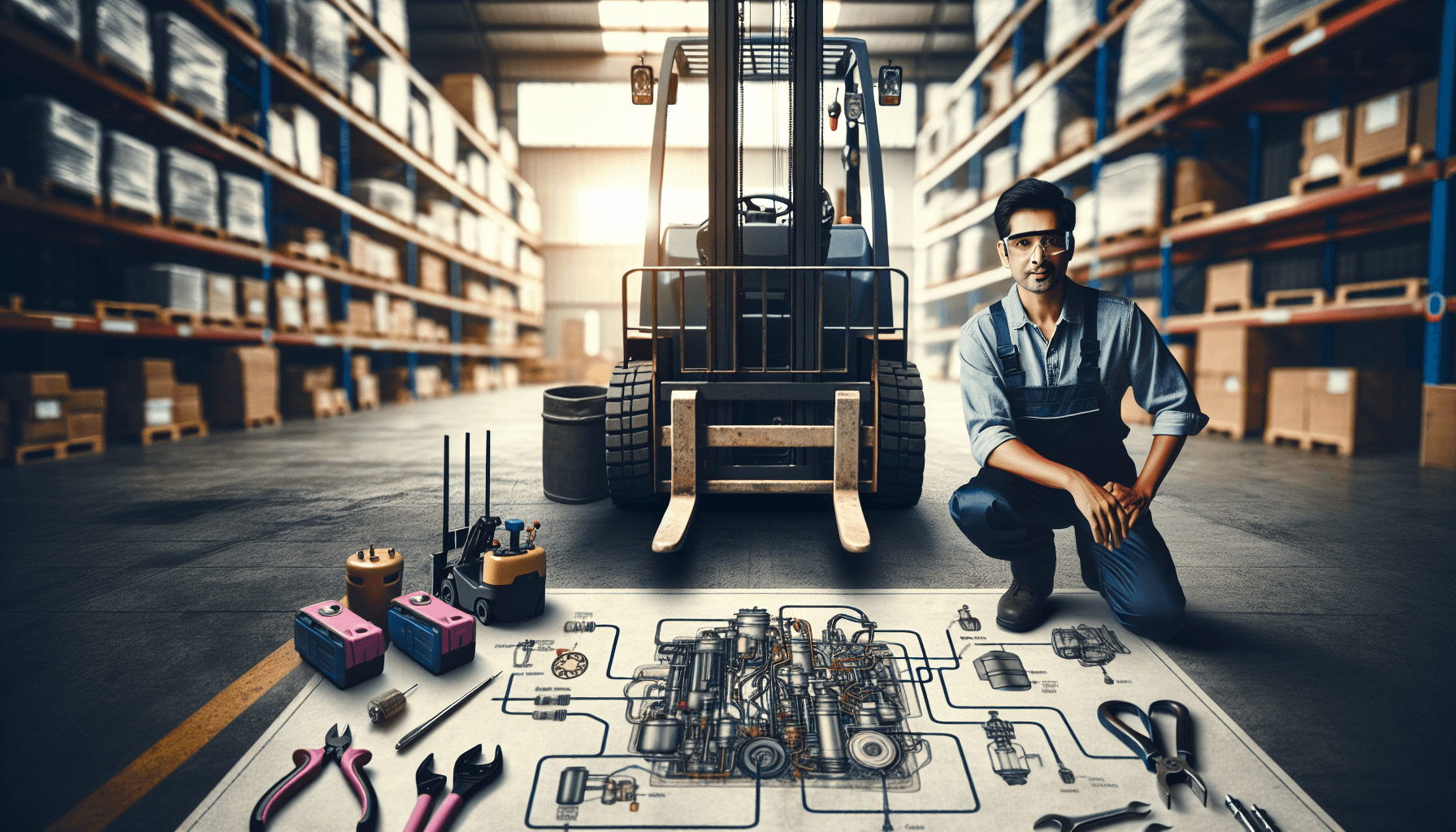

When it comes to maintaining efficient warehouse operations, one of the key areas that often gets overlooked is the forklift fuel system. Although it may seem like a small component, proper maintenance of the forklift fuel system is essential for ensuring smooth and uninterrupted operations. In this article, we will explore the importance of forklift fuel system maintenance and highlight the benefits it brings to warehouse optimization.

Enhanced Performance and Productivity

A well-maintained forklift fuel system plays a vital role in enhancing the overall performance and productivity within a warehouse. By regularly inspecting and servicing the fuel system, you can ensure that the forklifts are operating at their maximum efficiency. This includes checking and replacing fuel filters, inspecting fuel lines for leaks or blockages, and verifying proper fuel pressure levels.

When the forklift fuel system is functioning optimally, it allows for seamless and efficient operation of the equipment. This means faster movement of goods, quicker turnaround times, and increased productivity. By investing in regular maintenance and addressing any fuel system issues promptly, you can avoid costly downtime and foster a more productive workplace.

Improved Safety and Compliance

In a warehouse environment, safety should always be a top priority. An overlooked or neglected forklift fuel system can pose serious safety hazards. Fuel leaks, damaged fuel lines, or malfunctioning fuel valves can lead to accidents, fires, or even explosions. These incidents not only put the lives of workers at risk but can also cause damage to the warehouse infrastructure and inventory.

Regular maintenance of the forklift fuel system ensures that all components are in proper working condition and minimizes the risk of accidents. By inspecting fuel lines, valves, and connections, you can detect potential issues early on and address them promptly. This proactive approach helps create a safe working environment and ensures compliance with safety regulations and standards.

Longer Lifespan of Forklifts

Proper maintenance of the forklift fuel system also extends the lifespan of the equipment. By regularly cleaning or replacing fuel filters, you prevent debris and contaminants from reaching the engine, which can cause damage or reduce its performance. Additionally, regular inspection of fuel lines and valves helps identify any wear or damage, allowing for timely repairs or replacements.

When forklifts are well-maintained, they experience less stress and wear, leading to fewer breakdowns and costly repairs. This not only saves money in the long run but also ensures that the forklifts remain in service for a longer period, providing a higher return on investment.

Cost Savings and Efficiency

Investing in forklift fuel system maintenance can significantly reduce costs associated with fuel consumption. A properly maintained fuel system ensures that the forklifts are operating at their peak efficiency, which means they burn fuel more efficiently. Regular maintenance helps detect and address any issues that can lead to excessive fuel consumption, such as clogged filters or fuel leaks.

By improving fuel efficiency, you can control fuel costs and save money in the long run. Additionally, a well-maintained forklift fuel system reduces the likelihood of unexpected breakdowns or disruptions in warehouse operations. This means lower maintenance and repair costs and minimal downtime, allowing for greater efficiency and cost-effectiveness within the warehouse.

At HCO Innovations, we understand the importance of forklift fuel system maintenance and its impact on warehouse optimization. We offer turnkey forklift maintenance solutions to help businesses keep their forklifts running smoothly and efficiently. Our team of experts can inspect, service, and repair the fuel systems, ensuring optimal performance, enhanced safety, and cost-effective operations.

By utilizing our comprehensive maintenance solutions, you can focus on your core business operations while leaving the forklift maintenance to the experts. Visit our website here to learn more about how HCO Innovations can help you optimize your warehouse operations.