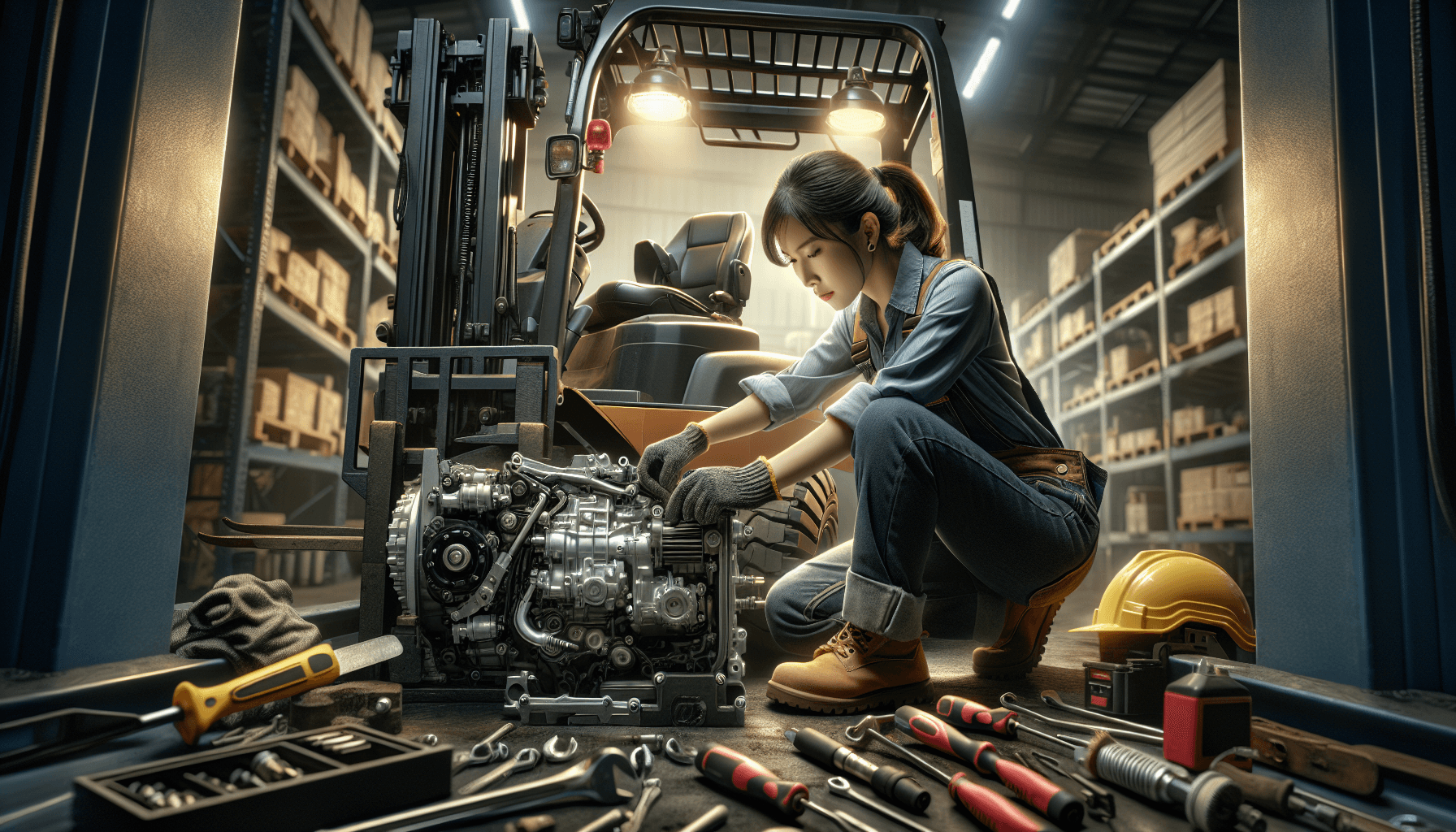

In warehouse operations, forklifts play a crucial role in ensuring the smooth flow of goods and materials. These powerful machines are responsible for lifting, stacking, and transporting heavy loads, making them an indispensable tool in any warehouse setting. To keep forklifts running at their best, it is vital to prioritize proper maintenance and care, including regular transmission maintenance.

The Importance of Forklift Transmission Maintenance

The transmission is a critical component of a forklift’s powertrain system. It is responsible for transmitting power from the engine to the wheels, allowing the forklift to move and navigate within the warehouse. Just like any mechanical system, the forklift transmission requires regular maintenance to ensure optimal performance and longevity.

Here are some key reasons why forklift transmission maintenance is of utmost importance:

1. Enhanced Performance

Regular transmission maintenance helps optimize the performance of your forklift. Over time, dirt, debris, and contaminants can accumulate in the transmission fluid, leading to decreased efficiency and performance. By properly maintaining the transmission, you can ensure smooth shifting, improved acceleration, and overall enhanced performance of the forklift.

2. Prevent Costly Repairs

Performing regular maintenance on the forklift transmission can help prevent major issues and costly repairs down the line. Neglecting routine maintenance can lead to transmission failure, which not only disrupts warehouse operations but also requires expensive repairs or even the replacement of the entire transmission. By investing in regular maintenance, you can catch any potential problems early on and address them before they escalate into more significant issues.

3. Extended Lifespan

Proper transmission maintenance can significantly extend the lifespan of your forklift. Routine fluid checks, filter replacements, and inspections can help identify and resolve potential issues that can lead to premature wear and tear. By taking care of your forklift’s transmission, you can maximize its longevity and ensure it remains in top working condition for years to come.

4. Improved Safety

Maintaining the transmission of your forklift is crucial for promoting a safe working environment. A well-maintained transmission ensures that the forklift operates smoothly and responds accurately to the operator’s commands. Any issues with the transmission, such as delayed shifting or slipping gears, can compromise the safety of both the operator and others working in the warehouse. Regular maintenance helps prevent these safety hazards and ensures that the forklift remains reliable and safe to use.

At HCO Innovations, we understand the importance of forklift transmission maintenance in optimizing warehouse operations. Our turnkey forklift maintenance solutions provide comprehensive services to keep your forklifts running smoothly and efficiently. We offer regular inspections, fluid changes, filter replacements, and repairs to ensure that your forklift transmissions are always in top-notch condition.

With our expertise and commitment to warehouse optimization, we can help improve safety, productivity, and cost-effectiveness within your warehouse operations. By prioritizing forklift transmission maintenance, you can experience the benefits of optimized performance, minimized downtime, and increased return on investment.

Don’t wait for transmission issues to hamper your warehouse productivity. Contact our team at HCO Innovations today to learn more about our turnkey forklift maintenance solutions and keep your warehouse operations running seamlessly.