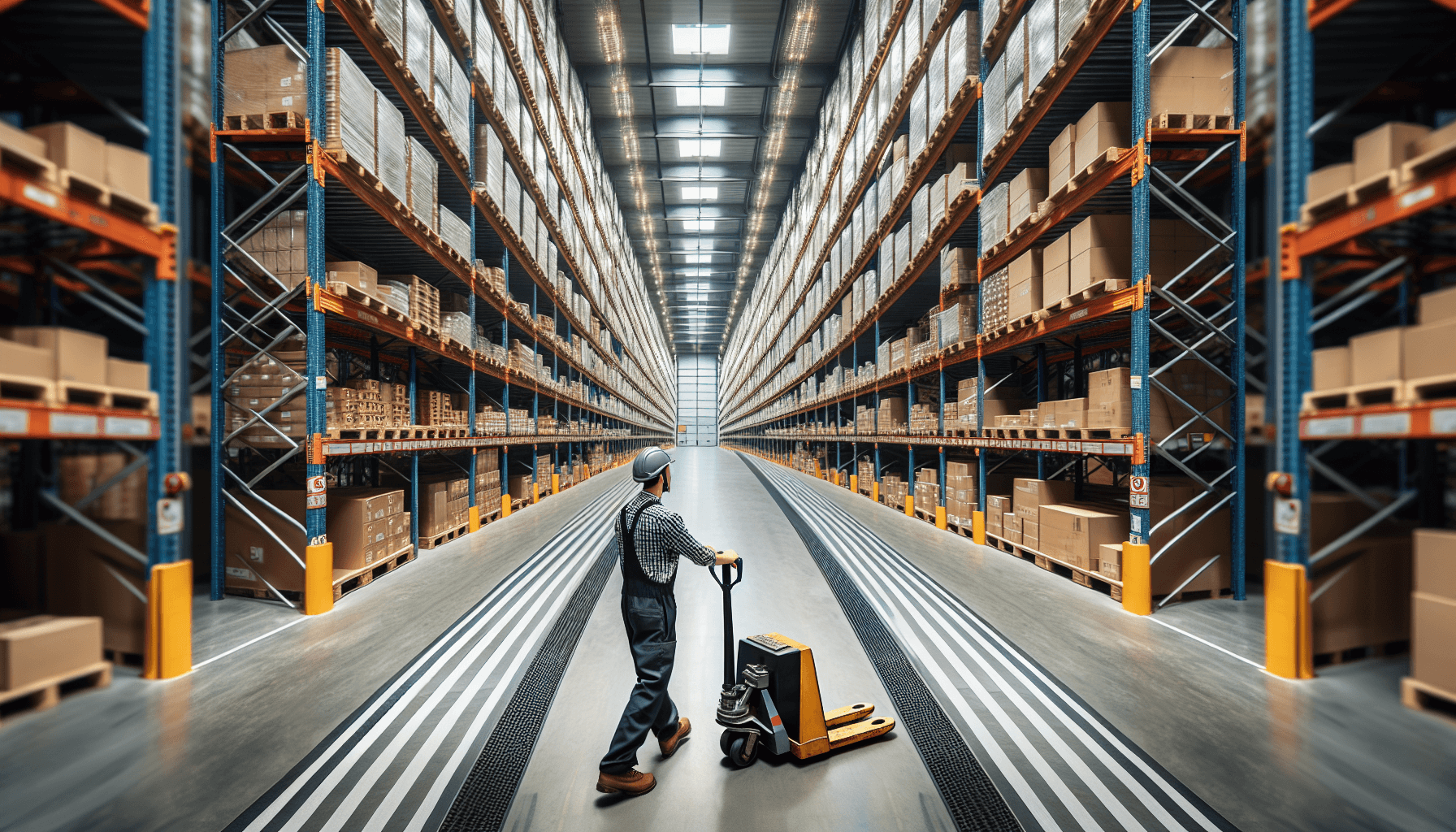

When it comes to warehouse operations, there are many factors that contribute to the overall productivity, efficiency, and safety of the facility. One often overlooked aspect is the maintenance of clear and safe walkways within the warehouse. While it may seem like a trivial matter, the importance of keeping walkways clear cannot be overstated.

The Hazards of Blocked Walkways

Blocked walkways pose a significant risk to the safety of employees and can lead to a variety of accidents and injuries. When walkways are cluttered with obstacles such as pallets, boxes, or equipment, it becomes difficult for employees to navigate through the warehouse without potentially tripping or colliding with objects. This can result in injuries ranging from minor cuts and bruises to more severe sprains, fractures, or even head injuries.

In addition to the risk of physical injuries, blocked walkways can impede the smooth flow of material handling equipment such as forklifts, pallet jacks, and hand carts. This can cause delays in the movement of goods, leading to decreased productivity and inefficiencies in warehouse operations. It can also impact the ability to meet customer demand and fulfill orders in a timely manner.

The Benefits of Clear Walkways

On the other hand, maintaining clear walkways in the warehouse provides a multitude of benefits, enhancing safety, productivity, and overall efficiency. Here are some key advantages:

- Promotes Safety: Clear walkways allow employees to move freely and safely throughout the warehouse, reducing the risk of accidents and injuries. By providing unobstructed paths, employees can maintain better visibility and awareness of their surroundings, enabling them to avoid potential hazards.

- Optimizes Workflow: When walkways are clear, material handling equipment can move efficiently and unobstructed, preventing bottlenecks and delays. This keeps the workflow smooth and ensures that goods are transported and distributed in a timely manner.

- Improves Employee Productivity: With clear walkways, employees can easily access the required items, materials, and equipment, saving time and effort. This allows them to focus more on their tasks and be more productive, contributing to the overall efficiency of warehouse operations.

- Facilitates Inventory Management: Clear walkways provide better visibility and access to inventory shelves, making it easier for employees to locate and pick items. This improves inventory management accuracy and reduces the time spent searching for products.

Implementing advanced technologies such as forklift pedestrian detection systems can further enhance the safety of walkways. These systems use sensors and alarms to detect and alert forklift operators about the presence of pedestrians in their vicinity, preventing potentially dangerous collisions.

Best Practices for Maintaining Clear Walkways

To ensure the ongoing maintenance of clear walkways in your warehouse, consider implementing the following best practices:

- Establish clear policies and procedures regarding walkway cleanliness and organization. Make sure that all employees are aware of these guidelines and regularly reinforce them through training and reminders.

- Assign designated areas for storing equipment, pallets, and other items, ensuring they are kept off the main walkways. Use signage or floor markings to clearly define these storage areas.

- Regularly inspect and clean walkways throughout the day, removing any obstacles or debris promptly. Encourage employees to report any potential hazards or concerns they come across.

- Invest in appropriate storage solutions such as racks, shelving units, and bins to better organize and store items, minimizing the chances of them spilling onto walkways.

- Consider implementing automated systems to track and monitor the movement of inventory and equipment within the warehouse. These systems can help identify any potential congestion points and allow for better planning and optimization of walkway layouts.

By implementing these best practices and prioritizing the maintenance of clear walkways, warehouse managers can create a safer and more efficient working environment for their employees. The investment in time and effort to maintain clear walkways pays off in the form of increased productivity, minimized accidents, and improved overall warehouse performance.

Remember, the safety and well-being of your employees should always be a top priority, and keeping walkways clear is a crucial step in achieving that goal.