Smarter Warehouse Layouts Start with Better Planning

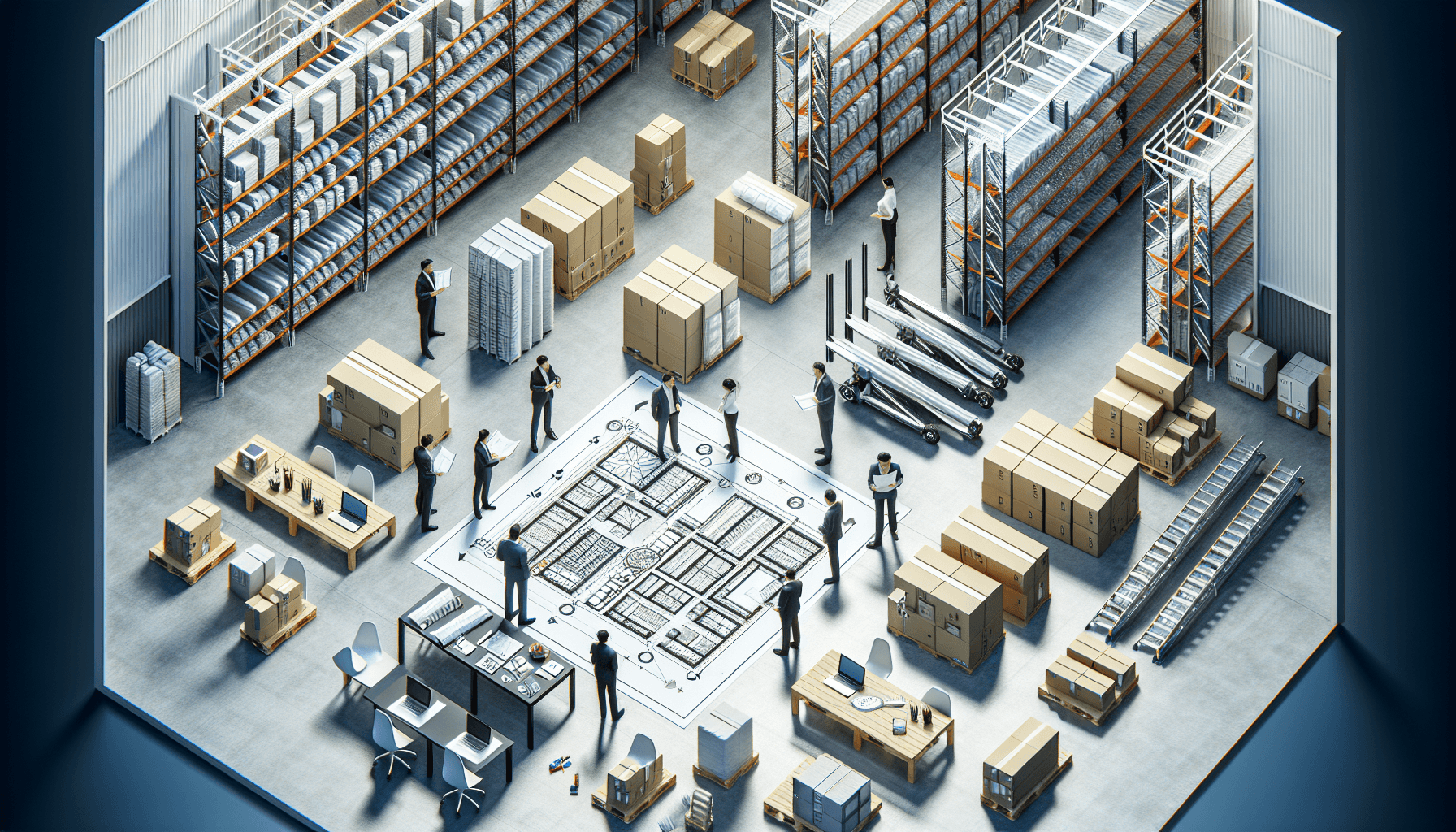

There’s no getting around it—warehouse layout planning plays a huge role in how well your operation runs. From storage density to order turnaround times, the way you arrange your space affects everything. At HCO Innovations, we’ve seen firsthand how strategic layout planning can transform a warehouse from cluttered and chaotic to clean, efficient, and profitable.

Get More Out of the Space You Already Have

Most warehouses are using up less space than they think. Whether it’s awkward racking, oversized aisles, or simply poor slotting decisions, wasted space adds up fast. We help identify those gaps through layout evaluation—measuring how inventory is stored, how equipment moves, and where slowdowns occur.

With that info, we rework your layout to unlock hidden capacity. Sometimes it’s as simple as rearranging zones, other times it’s vertical storage or smart racking. Either way, we make the most of every square foot so you can delay—or avoid—expansion costs entirely.

Better Flow, Faster Fulfillment

Warehouse layout isn’t just about storage—it’s about movement. We map out the natural paths your team and equipment take, and we design the space to support it. That means fewer backtracks, shorter pick routes, and less time wasted searching or walking.

Fast-moving SKUs get placed close to packing areas. Receiving and putaway zones are streamlined. Cross-docking? We account for that too. When your layout supports how your team actually works, everything runs smoother. It’s simple, but it works.

Safety Isn’t Optional—It’s Designed In

Warehouse safety doesn’t happen by accident. We bake it right into the layout. From aisle width to signage to pedestrian lanes, we ensure your space supports safe forklift operations, reduces trip hazards, and meets compliance standards.

Small things—like better lighting in tight zones or relocating fire extinguishers—make a big difference. And when your team sees that safety matters, it boosts morale too. Nobody wants to work in a warehouse that feels dangerous.

Every Dollar Counts—Especially Now

Smart layout planning helps you cut costs without cutting corners. You reduce excess inventory by making stock more visible. You cut labor hours by reducing wasted steps. You ship faster and with fewer errors. All of it adds up to a leaner, more profitable operation.

And let’s be honest—when orders ship faster and more accurately, customers notice. That’s your reputation on the line. A good layout doesn’t just save you money—it grows your business.

We Don’t Do Cookie-Cutter Plans

At HCO Innovations, every warehouse layout plan we create is custom. We don’t guess—we measure. We analyze your current space, your product mix, your order patterns, and your team’s workflow. Then we build a plan that fits your goals and budget—not just what looks good on paper.

We can help whether you’re launching a new facility or trying to get more out of your current one. Our team has worked with warehouses across industries, and we know how to adapt proven strategies to your specific needs.

Let’s Rethink Your Warehouse Layout

If you’re ready to stop wasting space, reduce operational friction, and create a safer, more productive environment, we’re ready to help. Reach out to HCO Innovations to schedule your warehouse layout evaluation. Let’s build a space that actually works for you—not against you.