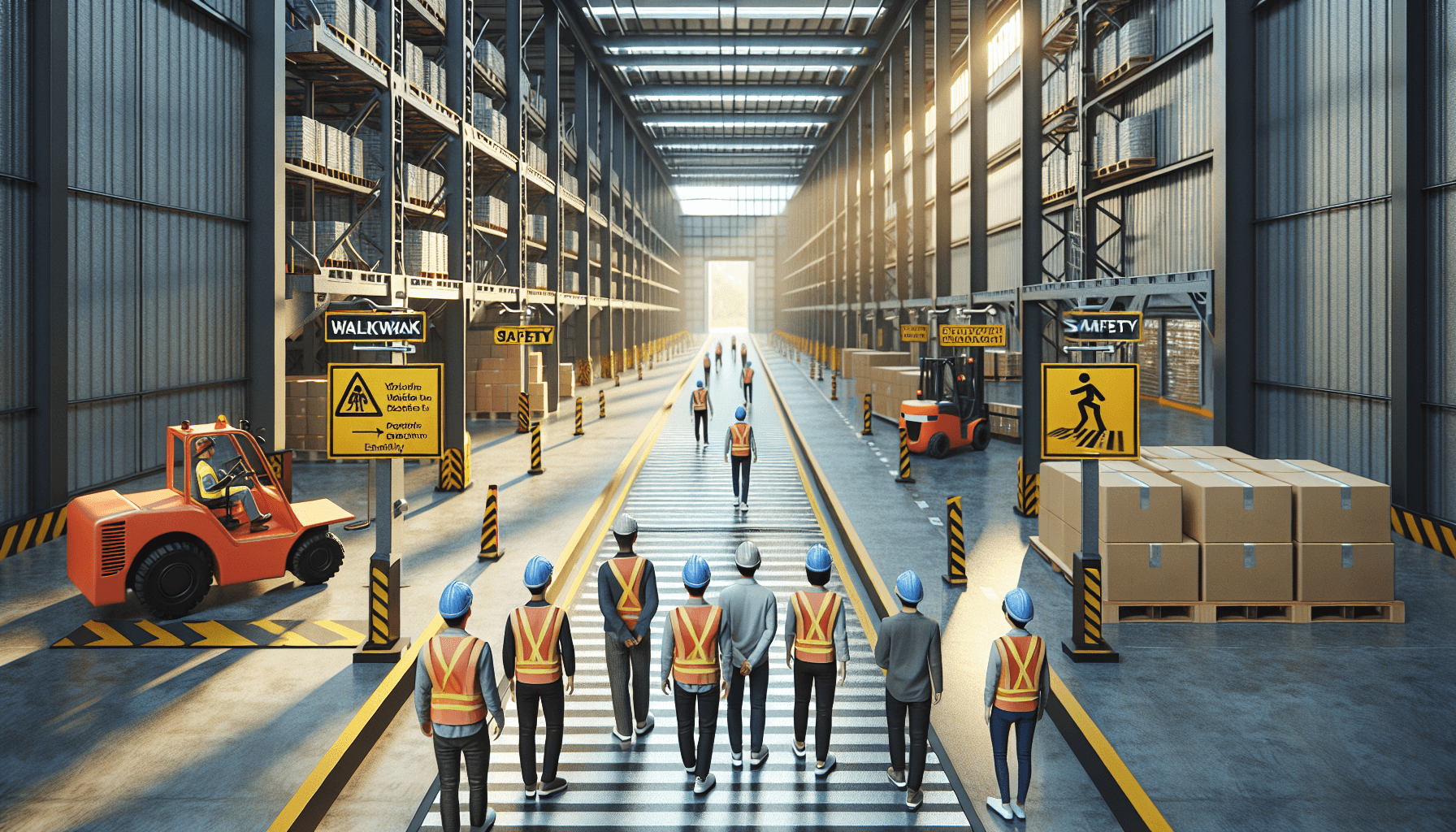

When it comes to warehouse operations, there are many factors that contribute to operational excellence. From optimizing processes and increasing productivity to reducing costs and ensuring the safety of employees, every aspect plays a crucial role. One area that often gets overlooked but is essential for a safe and efficient warehouse environment is walkway safety.

The Importance of Walkway Safety

Walkway safety is not just a matter of convenience or compliance with regulations. It is a vital aspect of warehouse operations that directly impacts productivity, efficiency, and overall operational excellence. Here are some key reasons why walkway safety should be a top priority for warehouse managers:

- Preventing Accidents and Injuries: The primary reason for prioritizing walkway safety is to prevent accidents and injuries. In a bustling warehouse environment, heavy machinery like forklifts and pallet jacks are constantly in motion, and pedestrians are also moving around. Ensuring clear and well-marked walkways helps to minimize the risk of collisions between pedestrians and moving equipment, reducing the chances of accidents and injuries.

- Enhancing Productivity: Safe walkways contribute to a more organized and efficient workflow. When employees have clearly designated paths to walk on, they can move around the warehouse easily without hindering the operations of forklifts or other equipment. This enhances productivity as there is no disruption or delay caused by congested walkways or accidents that may interrupt the workflow.

- Optimizing Material Flow: Well-designed walkways play a crucial role in optimizing material flow within a warehouse. By strategically positioning walkways, it becomes easier to navigate through different areas of the warehouse, ensuring smooth and efficient movement of goods. This reduces the time and effort required to locate and retrieve items, resulting in faster order fulfillment and improved customer satisfaction.

- Reducing Product Loss and Damage: In a busy warehouse setting, collisions between forklifts and pedestrians can lead to product loss or damage. By implementing proper walkway safety measures, such as barriers, signage, or the use of pedestrian detection systems, the risk of accidents and the resulting product loss or damage can be significantly reduced. This helps to maintain the quality and integrity of the goods being stored and shipped, saving both time and money in the long run.

These are just a few examples of how prioritizing walkway safety can have a significant impact on warehouse operations. It is clear that walkway safety is not an isolated concern but an integral part of overall operational excellence.

HCO Innovations understands the importance of walkway safety and offers innovative solutions to enhance safety in warehouse environments. One such solution is their Forklift Pedestrian Detection System, which uses advanced technology to detect and alert forklift operators of nearby pedestrians. This system helps to prevent accidents and ensure the safety of warehouse personnel. Learn more here.

By investing in effective walkway safety solutions, warehouse managers can create a safer work environment, minimize the risk of accidents and injuries, optimize material flow, and ultimately enhance operational excellence. Prioritizing walkway safety is a proactive and responsible approach that not only protects employees but also improves overall productivity and efficiency in warehouse operations.