A loading dock can be a busy place with all the activity and equipment in use. At loading docks and in warehouses, mishaps can and do occur. One out of every four warehouse injuries happens at the loading dock. When they happen, those injuries tend to be serious. Sometimes fatal mishaps at loading docks also create economic losses. Work stops, equipment gets shut down, products are damaged. Safety is so important no matter what type of work you do at the dock or in the warehouse, whether you drive a truck, check-in freight, operate a forklift break down, or build pallet loads. We’re going to look at the common causes of loading dock injuries and cargo damage. We’ll also show you how to spot and prevent typical hazards at the dock and in the warehouse, helping you be safe on the job and making the loading dock a safer place for everyone.

PPE Is Critical

Let’s start with the basics, personal protective equipment or PPE. At loading docks and in warehouses, PPE often includes eye protection, gloves, sturdy work shoes, and hard hats. The type of PPE used depends on the conditions and the kind of work you do. You may also need to use a dust mask, cold-weather clothing. If your employer and physician recommend one, you may also require back support. Know where emergency equipment is located, such as fire extinguishers, first aid kits, alarms, and telephones. Know how to use these items and what number to call in case of an emergency.

Let’s look at some of the most hazardous situations you may encounter at loading docks and warehouses. Unloading or loading a trailer happens every day and in just about every location you can think of. Most of the time, everything goes according to plan. However, even though it may all seem routine, you should always be on the lookout for what could go wrong. Here are some things you can do to help make loading or unloading a trailer a safe procedure every time.

Mind Shifting Loads

First of all, what do you need to keep in mind before you open the doors? If you said shifting loads, you’re right. Even if the load is transported only a few miles, it may have shifted on the trailer. Falling freight can be a hazard when you open the doors. So be sure to stand out of the way and always watch for falling freight when opening the cargo doors.

Slips, trips, and falls are the most common causes of injuries at loading docks. Floors at loading docks are usually designed for safe walking and standing, but liquids can make any surface unsafe. Water and ice can accumulate near docks, and forklifts can sometimes leak fluids. These hazards are even more dangerous when they’re near an open dock door. One small slip could flip you over the edge. Floors must be kept dry. Clean up any drips, leaks, or spills immediately.

Back Injuries Are No Joke

Back injuries are the nation’s number one workplace safety concern. More than 1 million workers suffer back injuries each year. Most back injuries don’t occur from a single incident. Usually, long-term abuse is what causes the problems. The best way to avoid back injuries is to avoid lifting, twisting, bending, or reaching overhead. Use material handling equipment for heavy loads. Operators should be adequately trained before using this type of specialized equipment. When you have to lift something manually, use good lifting techniques and never lift too much.

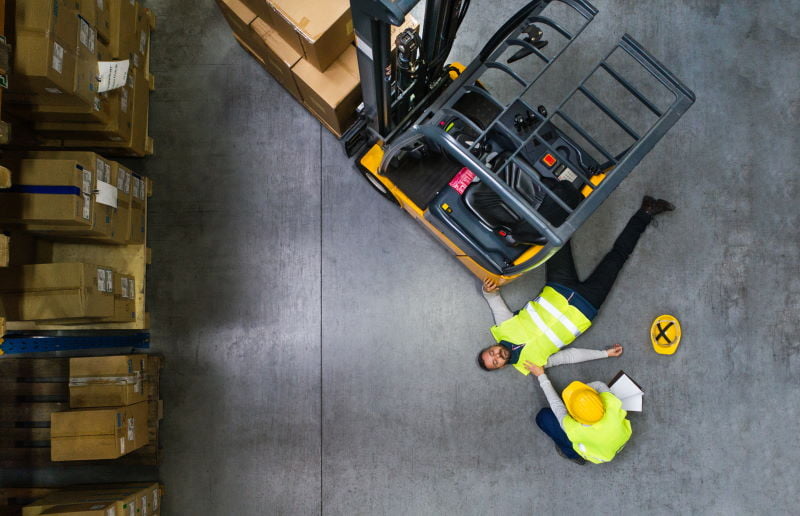

It’s crucial to be acutely aware of forklift traffic while working. Be especially mindful when there’s a forklift operating nearby. Forklift fleet operators are trained to yield to pedestrians, but they may not always see you. Listen, look, and check the convex mirrors at blind corners. It’s also a good idea to walk along the sides of an aisle or in walkways marked for pedestrian traffic. Forklifts steer from the rear wheels. Watch where the back end of the forklift swings out when it turns.

Follow Guidelines On How To Stack Loads

Your company probably has a policy or at least some preferences on where and how to stack loads. Make sure you follow those guidelines. There are some general safety rules to keep in mind when stacking loads in general. Don’t stack heavy loads on top of light loads. Heavy loads go under light ones. Smaller loads go on top of large loads.

A busy loading dock is a good thing. It’s a sign that your warehouse is thriving and healthy. Please do your part to keep it that way. Stay alert for hazards in and around loading dock and warehouse areas. A warehouse doesn’t have to be dangerous places to work. You can play a significant role in preventing mishaps. Practicing safety at the loading dock keeps you and your warehouse running smoothly.

Call HCO Innovations today for your warehouse safety evaluation.