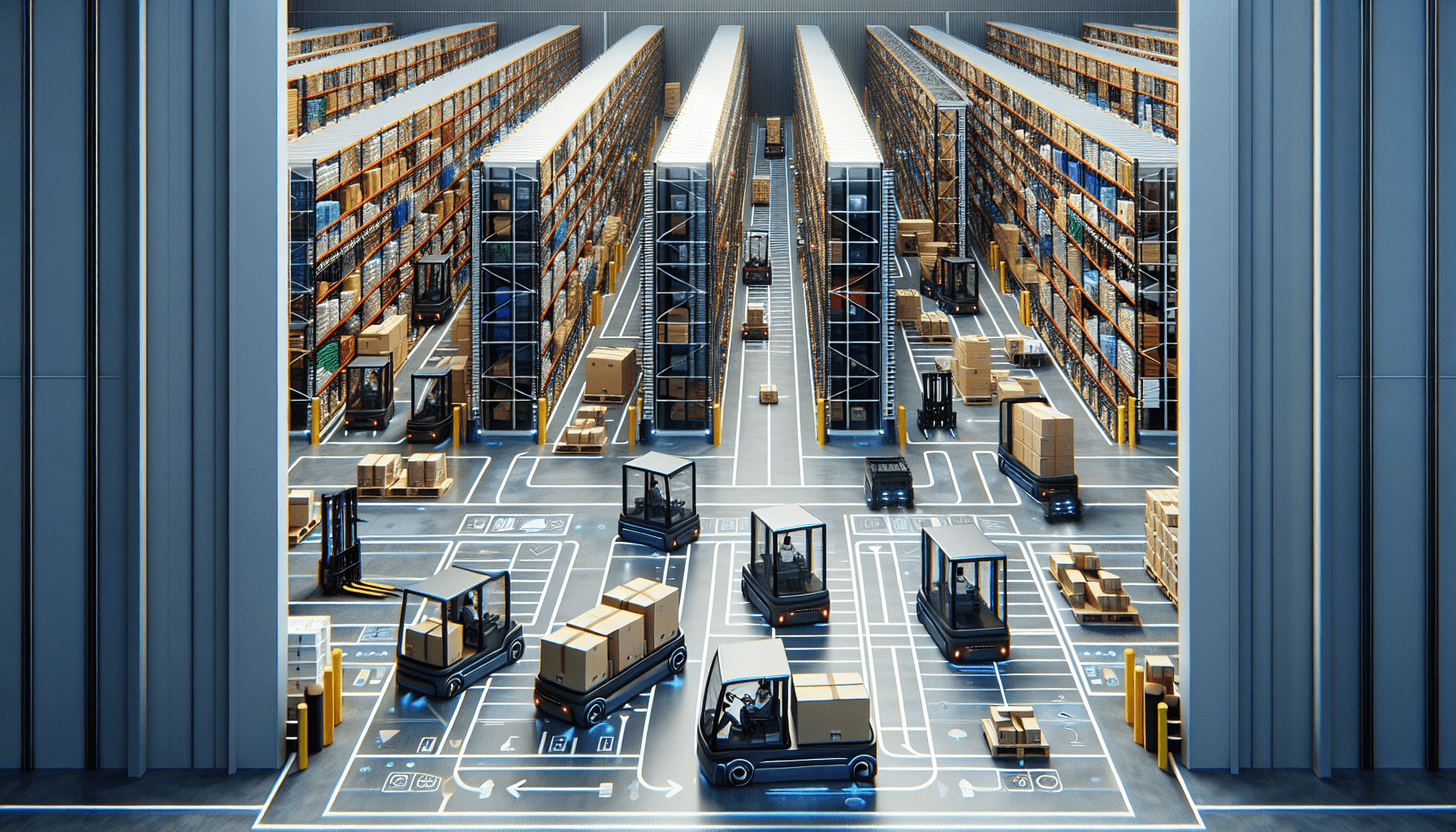

Warehouse space planning is a critical aspect of effective warehouse management. Properly utilizing the available space in a warehouse can lead to significant improvements in safety, productivity, and efficiency. One innovative solution that has revolutionized warehouse space planning is the use of Automated Guided Vehicles (AGVs).

The Benefits of AGVs in Warehouse Space Planning

AGVs are self-guided robotic vehicles that can perform various tasks within a warehouse environment without the need for human intervention. These vehicles are equipped with advanced sensors and navigation systems that allow them to safely navigate and transport goods within the facility. Here are some of the key benefits of using AGVs in warehouse space planning:

- Optimal Space Utilization: AGVs are designed to move efficiently through narrow aisles and tight spaces, allowing for maximum utilization of available warehouse space. By using AGVs, warehouses can minimize wasted space and ensure every inch of the facility is put to good use. This is especially beneficial for warehouses with limited space.

- Improved Inventory Management: AGVs can be integrated with the warehouse management system (WMS) to track inventory in real-time. This enables accurate and efficient inventory management, as AGVs can automatically pick up, transport, and put away goods based on the inventory data. With AGVs, warehouses can have a better view of their inventory levels and make data-driven decisions to optimize space utilization.

- Enhanced Safety: AGVs are equipped with advanced safety features to ensure the well-being of both human workers and the goods being transported. These vehicles are designed to detect obstacles and avoid collisions, reducing the risk of accidents in the warehouse. By using AGVs, warehouses can create a safer working environment and minimize the likelihood of injuries or damages.

- Increased Productivity: AGVs are capable of working 24/7 without breaks or fatigue, leading to increased productivity within warehouses. These vehicles can efficiently move goods from one location to another, eliminating the need for manual labor in repetitive and labor-intensive tasks. By automating these tasks, AGVs free up human workers to focus on more value-added activities, such as quality control and customer service.

- Improved Efficiency: AGVs can optimize the flow of goods within a warehouse by reducing unnecessary movement and minimizing wait times. These vehicles can be programmed to follow the most efficient routes, ensuring the timely delivery of goods and reducing overall lead times. With AGVs, warehouses can streamline their operations and improve order fulfillment speed.

AGVs have revolutionized warehouse space planning by providing a flexible and efficient solution for managing the movement of goods within a facility. These automated vehicles offer numerous benefits, including optimal space utilization, improved inventory management, enhanced safety, increased productivity, and improved efficiency. By incorporating AGVs into their warehouse operations, companies can optimize their space, save costs, and gain a competitive edge in the market.

HCO Innovations is a leading provider of AGV deployment solutions. Their expertise in warehouse optimization, including the implementation of AGVs, has helped numerous companies achieve significant improvements in their space utilization and operational efficiency.

By leveraging HCO Innovations’ AGV deployment solutions, companies can benefit from their extensive experience in warehouse space planning. HCO Innovations offers customized AGV solutions tailored to the specific needs of each warehouse, ensuring optimal performance and seamless integration with existing systems. With their expertise, companies can maximize their warehouse space and fully leverage the benefits of AGVs.

In conclusion, AGVs play a crucial role in improving warehouse space planning. These robotic vehicles offer several advantages, including optimal space utilization, improved inventory management, enhanced safety, increased productivity, and improved efficiency. By partnering with experienced providers like HCO Innovations, companies can unlock the full potential of AGVs and transform their warehouse operations.