Warehouse operations play a crucial role in the success of any business. Efficient and streamlined warehouse processes directly impact customer satisfaction, profitability, and competitive advantage. As the demands of customers continue to evolve, businesses are constantly seeking ways to reduce lead times and enhance overall efficiency. One solution that has gained significant attention and proven to be effective in achieving these goals is the implementation of Automated Guided Vehicles (AGVs).

What are AGVs?

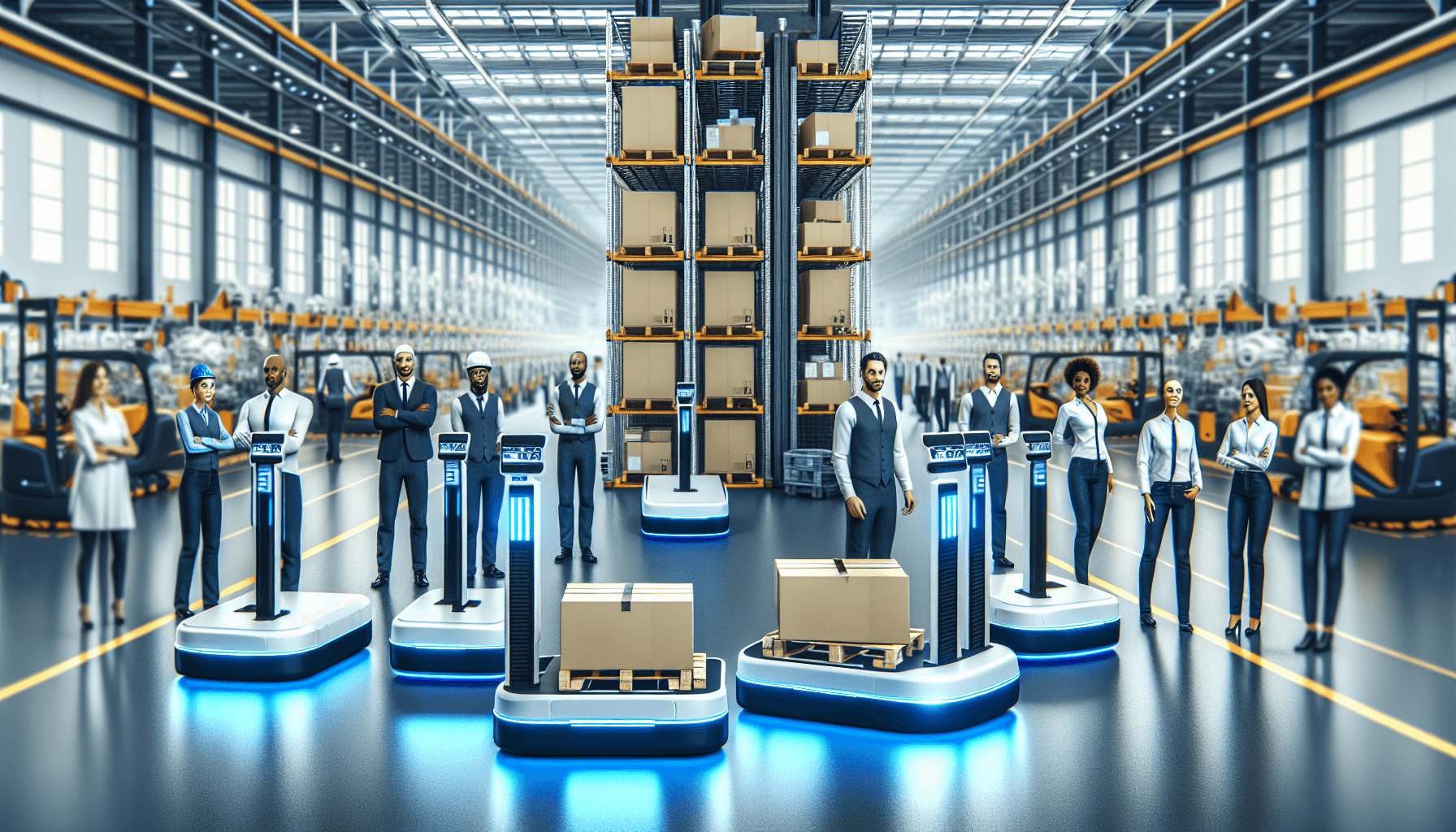

AGVs, or Automated Guided Vehicles, are autonomous vehicles designed to perform various material handling tasks within a warehouse or distribution center. These vehicles are equipped with advanced sensors and navigation systems to navigate through the warehouse environment without the need for human intervention. AGVs can transport goods, materials, and products with precision and efficiency, thereby optimizing warehouse operations.

The implementation of AGVs offers several advantages for reducing lead times in warehouse operations:

- Improved Efficiency: AGVs can significantly enhance the efficiency of warehouse operations by automating repetitive tasks. They can handle tasks such as order picking, product transportation, and inventory management, eliminating the need for manual labor and reducing the time required to complete these tasks.

- Increased Productivity: AGVs operate 24/7 and can work at a consistent pace without breaks or fatigue. This increased productivity results in faster turnaround times and shorter lead times for fulfilling customer orders.

- Enhanced Safety: AGVs are designed with built-in safety features to prevent accidents, collisions, and damage to goods. This reduces the risk of delays caused by accidents or injuries, further contributing to shorter lead times.

- Optimized Space Utilization: AGVs are programmed to efficiently navigate through warehouse aisles, maximizing the use of available space. By reducing aisle widths and utilizing vertical storage systems, AGVs help optimize space utilization, leading to more efficient picking and storage processes.

One of the key factors influencing lead times in warehouse operations is the time required for order picking and fulfillment. AGVs are particularly effective in reducing lead times in this area:

AGVs can be programmed to follow specific paths and pick up items from designated locations within the warehouse. They can efficiently navigate through the warehouse, avoiding congestion and utilizing the most optimal routes. With their advanced navigation systems, AGVs can quickly pick and transport items, reducing the time required for order fulfillment. This results in faster order processing, shorter lead times, and improved customer satisfaction.

The HCO Innovations Difference

When it comes to implementing AGVs in warehouse operations, partnering with a trusted provider is crucial to achieve successful outcomes. HCO Innovations is a leading provider of warehouse optimization solutions, specializing in AGV deployment and implementation.

HCO Innovations offers a comprehensive range of AGV solutions tailored to meet the unique needs of different warehouses. Their team of experts works closely with clients to understand their specific requirements and develop customized AGV solutions that optimize warehouse processes and reduce lead times.

HCO Innovations’ AGV solutions are designed to enhance safety, productivity, and overall efficiency. By integrating AGVs into warehouse operations, businesses can reduce the time and effort spent on manual tasks, allowing employees to focus on more value-added activities. This not only improves lead times but also increases employee satisfaction and reduces the risk of injuries associated with manual material handling.

If you are looking to optimize your warehouse operations, reduce lead times, and enhance overall efficiency, consider implementing AGVs with the help of HCO Innovations. Their expertise and industry-leading solutions can transform your warehouse into a highly efficient and productive operation.

For more information on AGV deployment and how it can benefit your warehouse operations, visit HCO Innovations website.