Forklifts play a crucial role in warehouse operations, facilitating the movement and transportation of goods and materials. With their ability to handle heavy loads and maneuver in tight spaces, forklifts are indispensable tools in modern warehouses. However, ensuring the safety of forklift operations is of paramount importance to prevent accidents and injuries. One critical aspect that contributes to forklift safety is the proper utilization of forklift batteries.

The Importance of Forklift Batteries in Warehouse Safety

Forklift batteries are not just power sources for these vehicles; they directly impact warehouse safety in several ways. Let’s explore some important aspects:

- Reliable Power: Forklift batteries provide a reliable and consistent power source for the vehicles. This ensures that the forklifts operate at their optimal performance levels, reducing the risk of sudden power failure or breakdowns during critical operations.

- Reduced Downtime: By using high-quality forklift batteries, warehouses can minimize downtime caused by battery failures or the need for frequent recharging. This allows for continuous operations, increasing productivity and efficiency within the warehouse.

- Proper Maintenance: Forklift batteries require regular maintenance to ensure optimal performance and longevity. Following a comprehensive maintenance schedule, including checking fluid levels, cleaning battery terminals, and identifying any signs of wear or damage, is crucial. Regular maintenance helps identify potential issues before they escalate into safety hazards.

- Battery Charging Stations: Implementing dedicated battery charging stations within the warehouse layout promotes safe charging practices. Furnishing the charging areas with proper ventilation, spill containment systems, and clear signage ensures that employees follow safe procedures when handling and charging forklift batteries.

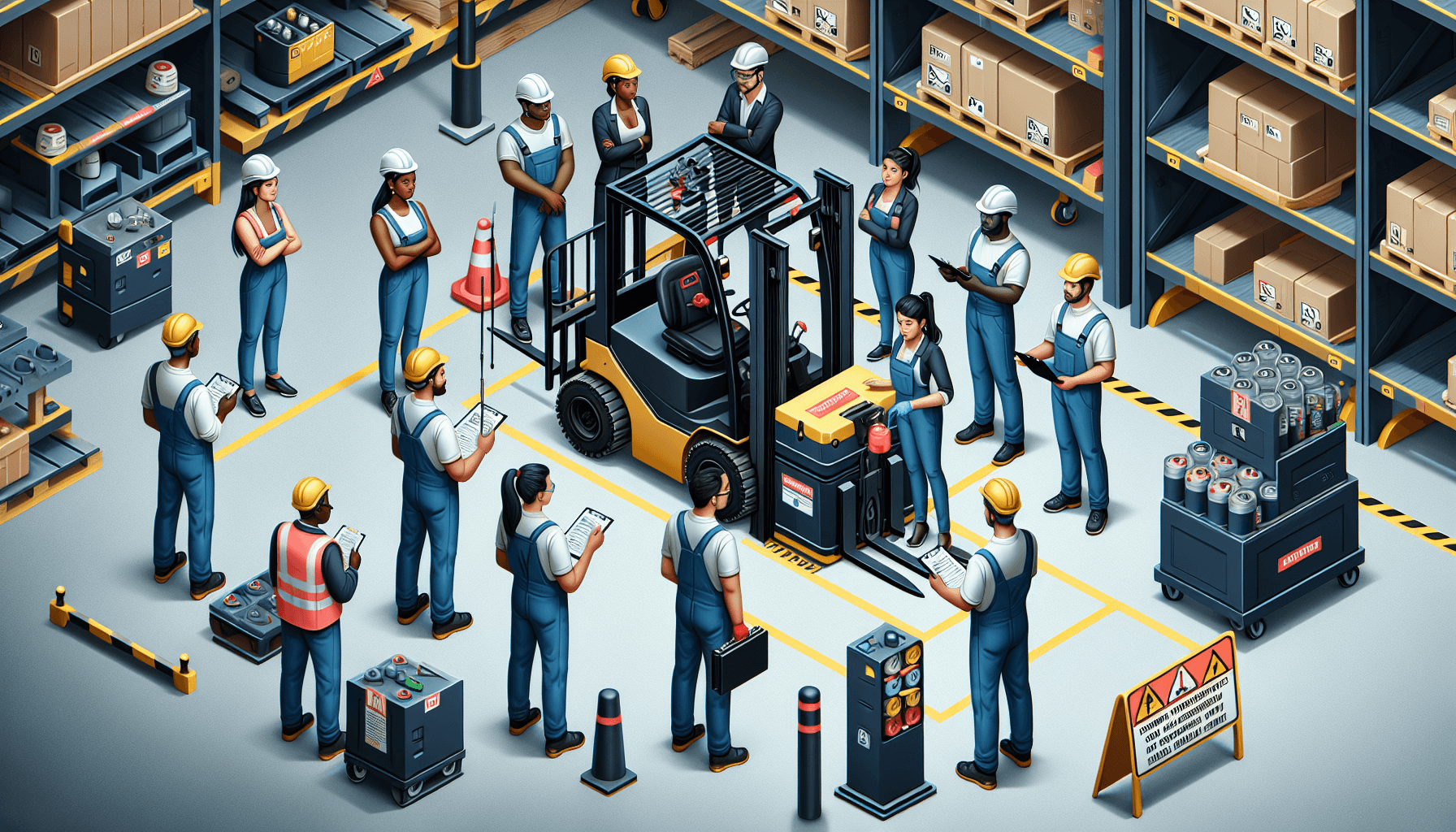

- Training and Education: Warehouse operators should provide comprehensive training and education to forklift operators regarding the proper handling and maintenance of forklift batteries. This includes training on battery charging procedures, identifying warning signs of battery malfunctions, and understanding the limitations and requirements of different types of batteries.

- Investing in Technology: HCO Innovations offers advanced forklift fleet power management solutions that can significantly enhance warehouse safety. Their innovative systems provide real-time monitoring of battery usage and performance, allowing operators to identify trends, anticipate potential issues, and take proactive measures to prevent accidents or downtime.

- Efficient Battery Recycling: Proper disposal and recycling of forklift batteries are essential for warehouse safety and environmental stewardship. Partnering with reputable battery recycling programs ensures compliance with regulations and minimizes the risk of hazardous materials polluting the environment.

By prioritizing the role of forklift batteries in warehouse safety, businesses can create a safer working environment for their employees while also optimizing productivity and reducing operational costs.

In conclusion, forklift batteries are more than just power sources. They play a vital role in ensuring warehouse safety by providing reliable power, reducing downtime, promoting proper maintenance, setting up dedicated charging stations, providing training and education, investing in advanced technologies, and implementing efficient battery recycling practices. To learn more about how HCO Innovations can help optimize forklift fleet power management and enhance warehouse safety, visit their website today.