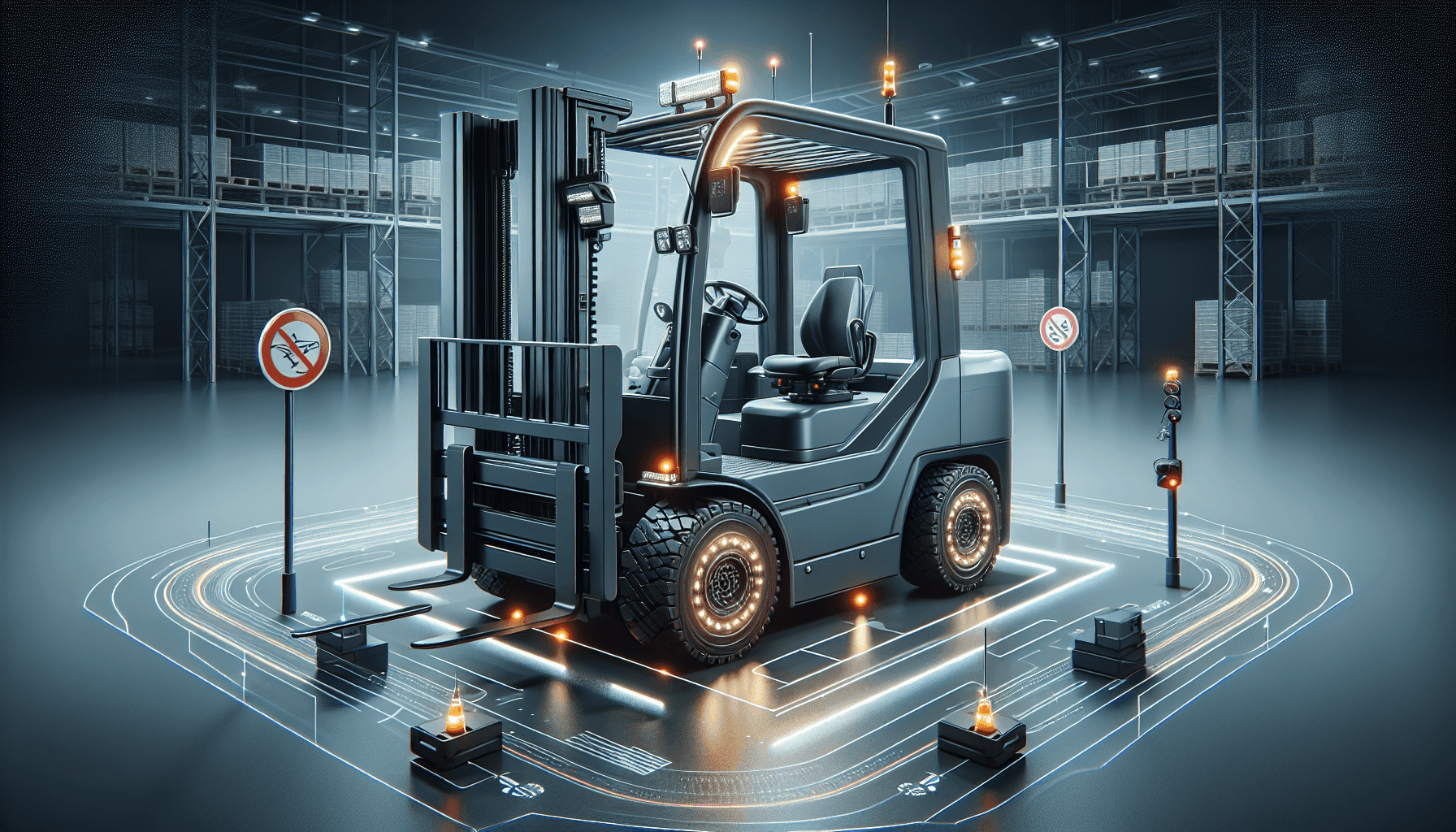

Forklifts play a crucial role in warehouse operations, allowing for the efficient movement of heavy loads. However, as with any machinery, there are risks involved, particularly when it comes to accidents. To mitigate these risks and prioritize safety in the workplace, it is important to consider the design of the forklift itself.

The Importance of Forklift Design in Accident Prevention

When it comes to accident prevention in warehouses, the design of the forklifts used can make a significant difference. Here are some key factors to consider:

- Visibility: Forklifts with clear visibility features, such as panoramic views, mast-mounted cameras, or transparent panels, can greatly reduce the risk of accidents. Operators can have a better view of their surroundings and any potential hazards, ensuring safer maneuvering.

- Ergonomics: Well-designed forklifts prioritize operator comfort and ergonomics. This can include adjustable seats, easy-to-reach controls, and ergonomically designed controls that reduce operator fatigue. When operators are comfortable, alert, and less fatigued, the chances of accidents decrease.

- Stability: Unstable loads or an imbalance in weight distribution can lead to forklift tip-overs. Forklifts with advanced stability features, such as auto-leveling systems or load sensors, can help prevent such accidents. These features help maintain the stability of the forklift and reduce the risk of tipping.

- Speed and Acceleration Control: Forklifts with precise speed and acceleration control systems enable operators to navigate the warehouse safely, especially in congested areas. Features like adjustable speed limits and smooth acceleration and deceleration help prevent collisions and allow for better control over the forklift’s movement.

- Emergency Stop Systems: In case of an emergency, quick and effective stopping of the forklift is paramount. Forklifts equipped with emergency stop buttons or automatic braking systems can help prevent accidents by rapidly bringing the forklift to a halt in critical situations.

Investing in forklifts with these design features not only enhances safety but also increases productivity. The ability to operate efficiently while minimizing the risks of accidents results in a more productive and effective warehouse environment.

At HCO Innovations, we understand the importance of warehouse safety and accident prevention. We offer comprehensive solutions to help optimize warehouse operations, including warehouse safety evaluations. Our expert team can assess your existing forklift fleet and recommend improvements based on the latest safety standards and best practices.

With our warehouse safety evaluation services, we evaluate various aspects of your warehouse, including forklift design and safety features. By identifying potential hazards and suggesting appropriate modifications, we can help you create a safer working environment for your employees.

Don’t wait until an accident happens. Take proactive measures to enhance safety in your warehouse today. Contact us to schedule a warehouse safety evaluation and let our experts guide you towards a safer and more efficient operation.