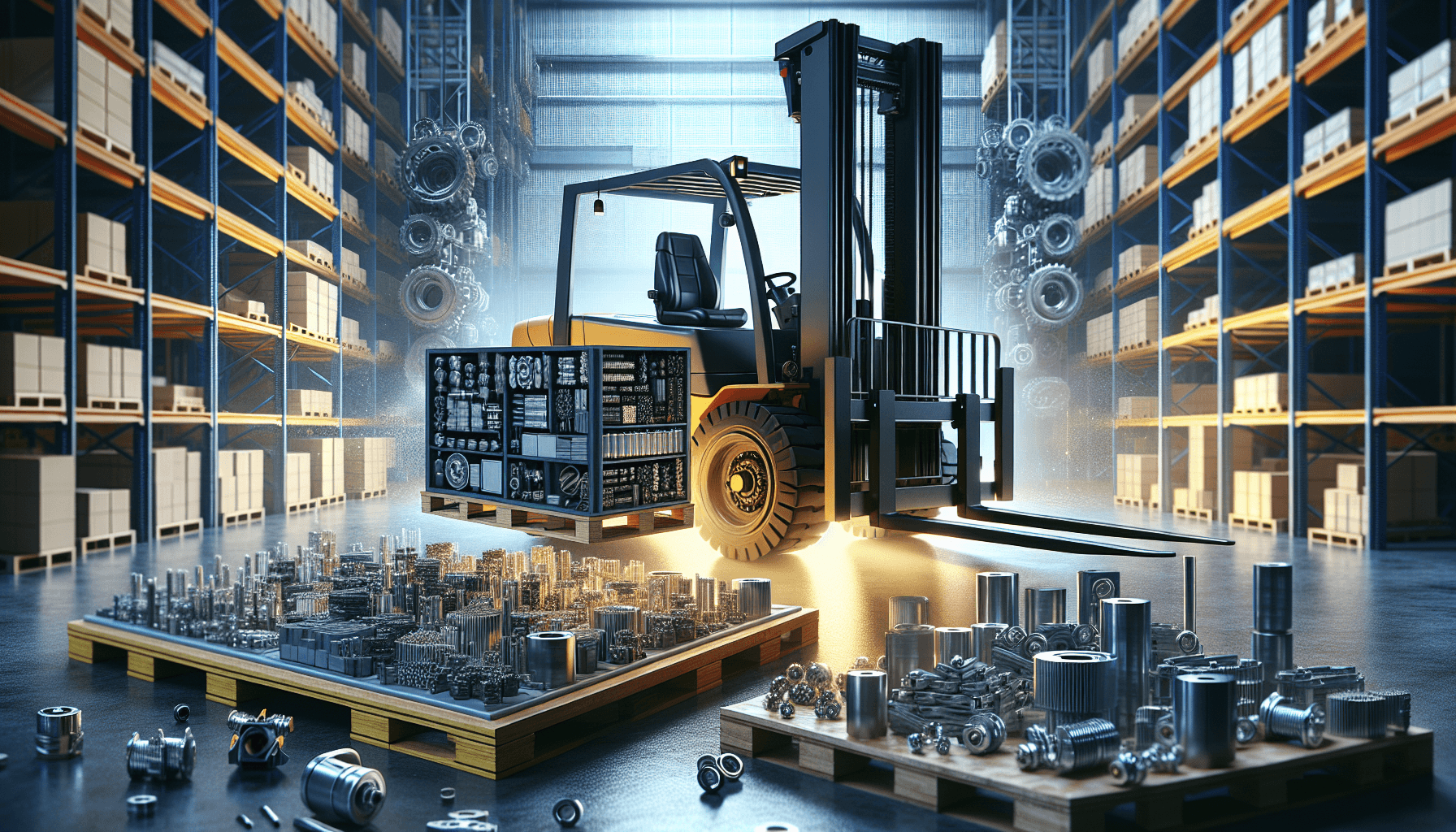

As businesses strive to achieve lean manufacturing processes, one vital element that should never be overlooked is the role of forklift power. Forklifts play a critical role in warehouse operations, and their efficiency and reliability can significantly impact the overall productivity of a company. In this article, we will explore the importance of forklift power in lean manufacturing and how HCO Innovations can help optimize your forklift fleet for maximum performance.

Why Forklift Power Matters

When it comes to warehouse operations, time is money. Forklifts are essential tools for moving heavy loads and materials quickly and efficiently. The power and performance of your forklift fleet can have a direct impact on the speed and effectiveness of your operations. Here’s why forklift power matters:

- Faster operations: Powerful forklifts can move loads more quickly, allowing for faster pick and drop-off times. This helps reduce downtime and increases overall operational efficiency.

- Increased productivity: A well-powered forklift fleet can handle larger loads, reducing the number of trips required. This can significantly increase productivity and throughput.

- Improved safety: Forklifts with sufficient power can handle heavy loads more easily, minimizing the risk of accidents or damage to goods and equipment. This ensures a safer working environment for warehouse staff.

- Reduced fuel consumption: Power-efficient forklifts consume less fuel, resulting in cost savings and reduced environmental impact.

HCO Innovations: Optimizing Forklift Power for Lean Manufacturing

At HCO Innovations, we understand the critical role that forklift power plays in lean manufacturing. We specialize in warehouse optimization solutions that enhance safety, productivity, efficiency, and cost-effectiveness. Our team of experts can help you optimize your forklift fleet’s power for maximum performance and provide customized solutions tailored to your specific needs.

One of our key services is forklift fleet power management. We use advanced technologies and data analysis to assess your current fleet’s power requirements and identify opportunities for improvement. By analyzing factors such as load capacity, operating conditions, fuel consumption, and maintenance history, we can help you make data-driven decisions to optimize your fleet’s power settings.

Our forklift power management solutions include:

- Power assessment: We conduct a comprehensive analysis of your forklift fleet’s power requirements to identify areas for improvement.

- Load optimization: We help you optimize load distribution and weight capacity to maximize efficiency and reduce strain on your forklifts.

- Power setting optimization: We fine-tune your forklifts’ power settings to ensure optimal performance while minimizing fuel consumption.

- Maintenance and monitoring: We provide regular maintenance and monitoring services to ensure that your forklifts are operating at their peak performance and identify any potential issues before they become major problems.

By partnering with HCO Innovations, you can unlock the full potential of your forklift fleet and achieve better results in your lean manufacturing initiatives. Our tailored solutions not only optimize forklift power but also contribute to overall warehouse efficiency and profitability.

Don’t let your forklift fleet hold you back from achieving lean manufacturing excellence. Contact HCO Innovations today to learn more about our forklift power management solutions and how we can help you streamline your warehouse operations. Together, we can power your success.

Click here to learn more about our forklift fleet power management solutions.