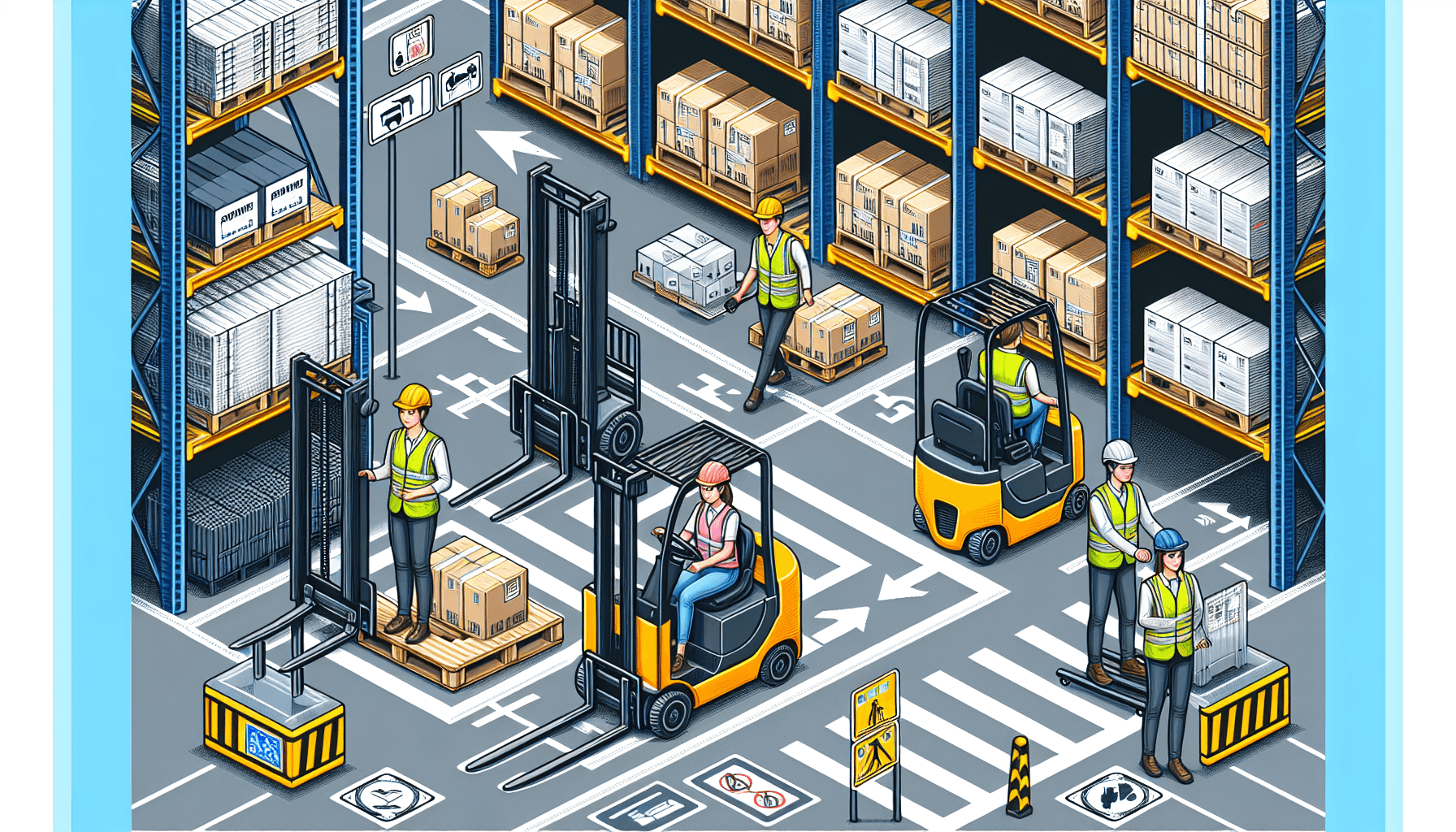

Forklifts play a crucial role in the day-to-day warehouse operations. These powerful machines, also known as industrial trucks, are used for lifting and moving heavy loads with ease. However, their capabilities come with inherent risks, making forklift safety a top priority for any warehouse operation. In this article, we will explore the essential role of forklift safety in achieving operational goals and how companies can benefit from prioritizing a safe work environment.

The Importance of Forklift Safety

Forklift accidents can result in severe injuries, property damage, and even fatalities. It is estimated that there are thousands of forklift-related accidents each year, many of which could have been prevented through proper safety measures. Implementing and promoting forklift safety not only protects the well-being of warehouse workers, but it also has a direct impact on the overall efficiency and productivity of the operation.

Warehouse managers and supervisors must understand that investing in forklift safety is an investment in their business’s success. By prioritizing the safety of their employees, they create a work environment that fosters productivity, reduces downtime, and minimizes the risk of accidents and injuries. Safe forklift operations can significantly contribute to the achievement of operational goals by improving the overall workflow and optimizing warehouse processes.

The Benefits of Forklift Safety in Warehouse Operations

1. Enhanced Productivity: When workers feel safe and confident operating forklifts, they can focus on their tasks and perform them efficiently. By providing comprehensive training programs and promoting safety protocols, warehouse operations can increase productivity and reduce the risk of accidents caused by negligence or lack of knowledge.

2. Cost Savings: Forklift accidents can lead to costly damages to inventory, equipment, and property. By implementing and enforcing safety measures, warehouse operations can potentially avoid these costly incidents. Additionally, a safe work environment reduces workers’ compensation claims and insurance premiums, resulting in significant cost savings for the company.

3. Improved Efficiency: Safe forklift operations contribute to a more streamlined and efficient workflow. With well-trained forklift operators, warehouse operations can minimize the time spent on unnecessary maneuvers or corrective actions due to accidents. This allows for smoother operations, faster turnaround times, and ultimately improves customer satisfaction.

4. Employee Morale and Retention: Prioritizing forklift safety creates a culture of care and concern for employees’ well-being. When workers feel that their employer values their safety, they are more likely to have higher job satisfaction and engagement. This, in turn, leads to better employee retention, reducing turnover rates, and the accompanying costs of recruitment and training.

5. Compliance with Regulations: Government regulations and safety standards exist to protect workers and ensure safe working conditions. By prioritizing forklift safety, warehouse operations can demonstrate compliance with these regulations and avoid penalties and legal issues. Compliance also enhances the company’s reputation, both among employees and customers.

In order to reap the full benefits of forklift safety, warehouse operations need to implement a comprehensive safety program. This program should include:

- Thorough training for forklift operators, including both theoretical knowledge and practical skills

- Ongoing refresher courses to keep operators up-to-date with the latest safety standards and practices

- Regular maintenance and inspections of forklifts to ensure they are in optimal working condition

- Clear communication of safety rules and expectations to all employees

- Proactive identification and mitigation of potential hazards in the warehouse

- Continuous monitoring and evaluation of safety practices to identify areas for improvement

By investing in these safety measures, warehouse operations can create a culture of safety and accountability, where forklift operators understand the importance of their role in maintaining a safe work environment. This, in turn, contributes to the achievement of operational goals by minimizing accidents, enhancing productivity, and improving overall efficiency.

At HCO Innovations, we understand the critical significance of forklift safety in warehouse operations. Our experienced team specializes in warehouse optimization solutions, including comprehensive warehouse safety evaluations. We can help you identify potential hazards, implement safety measures, and provide training programs to ensure that your forklift operations are safe and efficient. Click here to learn more about our warehouse safety evaluation services.

Why is forklift safety important in achieving operational goals?

Forklift safety is crucial in achieving operational goals because it helps prevent accidents, injuries, and damage to property. By prioritizing forklift safety, businesses can minimize downtime, reduce costs associated with accidents, and maintain a productive and efficient work environment.

What are some common forklift safety best practices?

Some common forklift safety best practices include proper forklift training and certification for operators, regular maintenance and inspections of forklifts, clear and designated traffic patterns in the workplace, wearing appropriate personal protective equipment (PPE), and ongoing safety awareness and communication.

How can forklift safety contribute to increased productivity?

Ensuring forklift safety can contribute to increased productivity by reducing the likelihood of accidents and equipment damage, thus minimizing downtime. By maintaining a safe work environment, forklift operators can work confidently and efficiently, resulting in higher productivity levels.

What are the consequences of neglecting forklift safety?

Neglecting forklift safety can have severe consequences such as accidents, injuries, fatalities, property damage, and legal liabilities. It can lead to increased insurance costs, loss of productivity, potential lawsuits, damage to a company's reputation, and negative impacts on employee morale.

Are there any legal requirements for forklift safety?

Yes, there are legal requirements for forklift safety. OSHA (Occupational Safety and Health Administration) in the United States mandates compliance with specific regulations, including operator training and certification, daily equipment inspections, and adherence to safe operating procedures.

How often should forklift operators receive training?

Forklift operators should receive initial training before operating a forklift and undergo refresher training every three years, or whenever there are significant changes in workplace conditions, equipment, or job tasks. Regular training helps ensure that operators stay updated on safety practices and regulations.

What are the key elements of forklift safety training?

The key elements of forklift safety training include understanding the principles of stability and center of gravity, safe load handling techniques, maneuvering and operating controls, recognizing and avoiding potential hazards, proper parking and shut down procedures, and emergency protocols.

How can I create a culture of forklift safety in my workplace?

To create a culture of forklift safety, it is important to lead by example, provide comprehensive training for all employees, establish clear safety policies and procedures, encourage open communication about safety concerns, regularly conduct safety audits and inspections, and reward and recognize safe behaviors.

Forklift Maintenance Best Practices for Increasing Workplace Efficiency.

Do you want to optimize your warehouse operations and reduce material handling costs? Look no further than HCO Innovations, a leading management consulting firm based in Raleigh, North Carolina.

The Importance of Forklift Maintenance

When it comes to warehouse efficiency, forklifts play a critical role in the smooth functioning of operations. Forklifts are an integral part of the material handling process, used for lifting and transporting heavy items within the warehouse.

However, like any other equipment, forklifts require regular maintenance to ensure they operate at their optimum level. Forklift maintenance is not only essential for extending the lifespan of the equipment but also for maximizing workplace efficiency and productivity.

Benefits of Regular Forklift Maintenance

Proper forklift maintenance holds numerous benefits for your warehouse operations. Let's take a look at some of the key advantages:

- Enhanced Safety: Regular maintenance ensures that your forklifts are in optimal condition, minimizing the risk of accidents and injuries in the workplace. This is especially crucial as forklift-related accidents can result in serious harm or even fatalities. By adhering to a comprehensive maintenance program, you can proactively identify and address potential safety issues.

- Optimized Performance: Well-maintained forklifts operate at their peak performance levels. Regular maintenance includes checking essential components such as engines, brakes, hydraulics, and tires. This helps prevent breakdowns and ensures that your forklifts are operating efficiently, saving time and improving overall productivity.

- Extended Lifespan: By implementing a proactive maintenance plan, you can significantly extend the lifespan of your forklift fleet. Regular servicing helps prevent major breakdowns and costly repairs, allowing you to get the most out of your investment.

- Reduced Downtime: Unplanned downtime due to forklift breakdowns can have a detrimental impact on your warehouse operations. Regular maintenance helps identify issues before they escalate, minimizing unexpected breakdowns and reducing productivity disruptions.

- Compliance with Regulations: Adequate forklift maintenance ensures that your equipment meets the required safety and compliance standards set by regulatory authorities. This helps avoid penalties or potential legal issues that may arise due to non-compliance.

Now that we understand the importance of regular forklift maintenance, let's explore some best practices that can help increase workplace efficiency.

Key Forklift Maintenance Best Practices

1. Follow Manufacturer's Guidelines: Each forklift manufacturer provides specific maintenance guidelines for their equipment. It's important to follow these recommendations and schedule routine maintenance accordingly. This includes tasks such as oil changes, filter replacements, and lubrication.

2. Regular Inspections: Conduct daily pre-shift inspections to identify any visible damage or issues that may impact the forklift's performance or safety. This includes checking tires, brakes, lights, and fluid levels. Any defects should be promptly addressed.

3. Train and Educate Operators: Proper training is key to maintaining forklift efficiency and safety. Educate your operators on best practices for operating the equipment, including proper handling techniques and avoiding unnecessary wear and tear.

4. Implement a Preventive Maintenance Program: Create a comprehensive preventive maintenance program that outlines regular servicing and inspection intervals. This program should include tasks such as fluid checks, filter replacements, battery maintenance, and thorough cleaning of the forklift.

5. Keep Records: Maintain detailed records of all maintenance activities, including inspection reports, servicing dates, and any repairs conducted. These records will help you identify patterns, track costs, and ensure that all necessary maintenance tasks have been completed.

6. Address Issues Promptly: If any issues or defects are identified during inspections or routine maintenance, it's crucial to address them promptly. Ignoring potential problems can lead to more significant issues down the line, resulting in costly repairs and extended downtime.

7. Work with a Trusted Partner: Consider partnering with a professional forklift fleet management provider like HCO Innovations. They can assist you with comprehensive maintenance solutions, including turnkey maintenance programs and fleet optimization strategies. Their expert team leverages advanced cost-tracking software and a collaborative approach to help you achieve significant cost reductions and operational efficiency.

By implementing these forklift maintenance best practices and partnering with experts like HCO Innovations, you can ensure that your warehouse operations run smoothly, reducing material handling costs and increasing workplace efficiency.

Ready to optimize your warehouse operations? Contact HCO Innovations today to learn more about their specialized services in warehouse optimization and forklift fleet management.