In an ever-evolving business landscape, managing risks in the workplace is of paramount importance. As companies strive to enhance safety, productivity, and efficiency, warehouse operations play a crucial role. One integral aspect of warehouse safety is forklift safety. Forklifts are indispensable tools in warehouse operations, enabling the movement and transportation of heavy loads with ease and efficiency. However, without proper safety measures, forklifts can pose significant risks to both operators and other personnel working in the warehouse.

The Importance of Forklift Safety

Implementing and adhering to comprehensive forklift safety protocols is essential for several reasons. First and foremost, it helps protect the safety and well-being of employees and other individuals present in the warehouse. Forklift accidents can lead to serious injuries or even fatalities, making it crucial to prioritize safety measures. By ensuring that forklift operators are trained, certified, and following proper safety procedures, the risk of accidents can be significantly reduced.

Moreover, forklift safety plays a vital role in risk management. In a warehouse setting, a single forklift accident can result in not only physical harm but also financial loss due to damaged products, equipment, and infrastructure. By prioritizing forklift safety, companies can mitigate the financial risks associated with workplace accidents.

Warehouse operators have a legal responsibility to ensure the safety of their employees and promote a safe working environment. Failure to comply with relevant safety regulations can lead to legal consequences, damaging the company’s reputation and financial stability. By embracing forklift safety as part of their risk management strategy, companies can demonstrate their commitment to workplace safety and regulatory compliance.

Key Elements of Forklift Safety

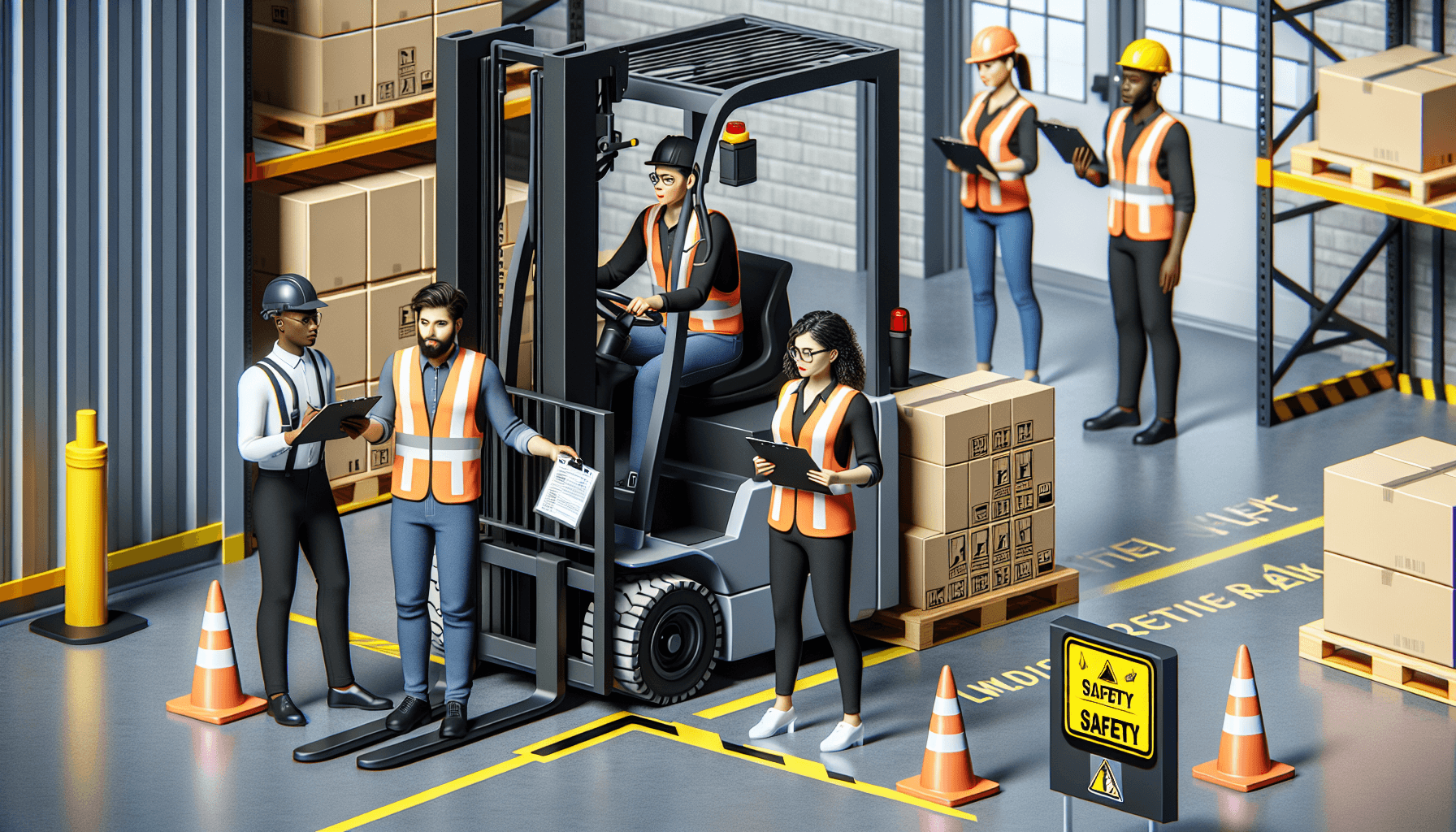

Creating a safe operating environment for forklifts involves a combination of training, equipment maintenance, and ongoing monitoring. Here are some key elements of forklift safety:

- Operator Training: Forklift operators must undergo comprehensive training on the safe operation of the equipment. They should be familiar with the forklift’s controls, understand load capacity limits, and know how to navigate different terrains safely. Ongoing training and refresher courses are also essential to ensure operators are up to date with the latest safety protocols.

- Regular Equipment Maintenance: Ensuring that forklifts are regularly inspected, serviced, and maintained is crucial. This includes checking brakes, tires, hydraulics, and other critical components to prevent mechanical failures that could lead to accidents.

- Clear Operating Procedures: Having clear operating procedures in place is vital to maintain a safe working environment. This includes guidelines on safe speeds, proper loading and unloading techniques, and protocols for handling hazardous materials. It’s important to regularly communicate and reinforce these procedures with forklift operators to ensure compliance.

- Proper Signage and Floor Markings: Clearly marking pedestrian walkways, traffic lanes, and restricted areas with appropriate signage and floor markings helps prevent accidents and promotes better visibility within the warehouse.

- Securing Loads: Properly securing loads on the forklifts not only prevents damage to products but also reduces the risk of tip-overs and injuries. Operators should be trained to assess the stability of the load and use appropriate securing measures such as straps, chains, or pallets.

By implementing these key elements of forklift safety, warehouse operators can significantly reduce the risk of accidents and create a safer working environment for all personnel.

HCO Innovations: Warehouse Safety Evaluation

HCO Innovations, based in Raleigh, NC, specializes in providing warehouse optimization solutions that enhance safety, productivity, efficiency, and cost-effectiveness. Their comprehensive approach to warehouse safety evaluation encompasses assessing and improving forklift safety protocols and practices.

With their expertise and experience in warehouse operations, HCO Innovations offers tailored solutions to identify potential safety hazards, recommend preventive measures, and develop customized training programs for forklift operators. By partnering with HCO Innovations for a warehouse safety evaluation, companies can ensure that their forklift operations are in compliance with safety regulations and industry best practices.

In conclusion, forklift safety plays a vital role in risk management within warehouse operations. By prioritizing forklift safety through comprehensive training, regular maintenance, clear operating procedures, proper signage, and load securing measures, companies can protect the safety of their employees and minimize the financial risks associated with workplace accidents. With the help of experts like HCO Innovations, warehouse operators can optimize their safety protocols and create a safer working environment.

What is the role of forklift safety in risk management?

Forklift safety plays a crucial role in risk management as it helps prevent accidents, injuries, and potential damage to property. By implementing proper forklift safety measures, such as regular inspections, operator training, and adherence to safety protocols, businesses can effectively manage and mitigate potential risks associated with forklift operations.

Why is it important to prioritize forklift safety?

Prioritizing forklift safety is essential because it helps protect the well-being of forklift operators, other employees, and visitors to the workplace. By prioritizing forklift safety, businesses can minimize the risk of accidents, injuries, and costly property damage, ensuring a safe and efficient work environment.

What are some common risks associated with forklift operations?

Common risks associated with forklift operations include collisions with pedestrians or other vehicles, tipping or overturning, falling objects from improperly loaded forklifts, and operator error due to lack of training or distractions. It is crucial to address these risks through comprehensive safety training, proper maintenance, and implementing safety protocols at all times.

What should be included in forklift safety training?

Forklift safety training should include topics such as the safe operation of the forklift, pre-shift inspections, proper loading and unloading techniques, safe maneuvering in different environments, understanding load capacities, and emergency procedures. It is important to provide both theoretical knowledge and practical hands-on training to ensure operators are well-prepared to handle forklift operations safely.

How often should forklift inspections be conducted?

Forklift inspections should be conducted on a regular basis, ideally before every shift. Pre-shift inspections help identify any potential issues or malfunctions that could jeopardize safety. Additionally, periodic comprehensive inspections should be performed by qualified technicians to ensure that all aspects of the forklift, including brakes, lights, hoists, and safety features, are functioning properly and up to standards.

What are some tips for improving forklift safety in the workplace?

Some tips for improving forklift safety in the workplace include: providing thorough operator training, ensuring proper maintenance and inspections, implementing clear traffic management plans, enforcing speed limits, using audible and visual warning devices, keeping work areas well-lit and free from obstructions, and promoting a safety culture where all employees are encouraged to report any safety concerns.

Are there specific regulations or standards for forklift safety?

Yes, there are specific regulations and standards for forklift safety. In the United States, the Occupational Safety and Health Administration (OSHA) provides regulations and guidelines for safe forklift operation, training requirements, and equipment requirements. It is important for businesses to comply with these regulations and stay informed about any updates or changes in forklift safety standards.

Using Technology to Enhance Forklift Safety in the Workplace.

In today's fast-paced and ever-evolving workplace, ensuring the safety of employees is of paramount importance. This is especially true in industries where heavy machinery, such as forklifts, are utilized on a regular basis. Companies like HCO Innovations are revolutionizing forklift fleet management by leveraging technology to enhance workplace safety.

The Role of Technology in Forklift Safety

Technology has transformed various aspects of our lives, and workplace safety is no exception. HCO Innovations recognizes the potential of technology to improve forklift safety and has developed innovative solutions to address common safety challenges. By employing advanced software and cutting-edge technologies, HCO Innovations provides clients with the tools they need to optimize their forklift fleet management and create a safer work environment.

One of the key technologies used by HCO Innovations is a state-of-the-art forklift telemetry system. This system utilizes real-time data collection and analysis to monitor forklift operations. Through the telemetry system, HCO Innovations can track crucial metrics such as speed, acceleration, and braking patterns. By analyzing this data, potential safety hazards can be identified, and appropriate measures can be taken to mitigate risks.

Another significant technological advancement is the integration of proximity sensors and cameras into forklifts. These sensors and cameras provide operators with a better view of their surroundings, reducing blind spots and the potential for accidents. HCO Innovations works closely with their clients to install and optimize these safety-enhancing features, ensuring maximum effectiveness.

Furthermore, HCO Innovations recognizes the importance of operator training in forklift safety. To meet this need, they have developed an innovative virtual reality (VR) training program. This program allows operators to experience realistic simulations of various workplace scenarios, providing them with hands-on experience in a safe and controlled environment. By using VR technology, HCO Innovations ensures that operators are well-prepared and confident in their abilities before they even step foot in a real forklift.

The Benefits of Technology-Enabled Forklift Safety

The adoption of technology-enabled forklift safety measures offers numerous advantages for businesses operating in industries where forklifts play a significant role:

- Reduced Accidents: By employing advanced telemetry systems, proximity sensors, and cameras, the risk of accidents and collisions can be significantly reduced. Real-time data analysis allows for the identification of potential hazards, and operators are equipped with the tools necessary to anticipate and prevent accidents.

- Increased Efficiency: Technology not only improves safety but also enhances operational efficiency. With tools like telemetry systems, managers can track forklift performance and identify areas of improvement. This enables companies to streamline their operations, reduce downtime, and increase overall productivity.

- Cost Savings: Enhanced safety measures can lead to substantial cost savings for businesses. By reducing accidents and the resulting damage to infrastructure and products, companies can avoid costly repairs and insurance claims. Moreover, improved efficiency translates to reduced fuel and maintenance expenses.

- Compliance with Regulations: The utilization of technology to enhance forklift safety helps companies meet regulatory requirements. By implementing safety measures such as proximity sensors and cameras, businesses can demonstrate their commitment to maintaining a safe working environment, ensuring compliance with relevant workplace safety standards.

- Enhanced Employee Morale: Investing in technology-enabled forklift safety measures shows employees that their safety and well-being are a top priority. This fosters a positive work environment and boosts employee morale and engagement.

HCO Innovations is dedicated to helping businesses harness the power of technology for superior forklift fleet management and enhanced workplace safety. Their comprehensive approach and tailored solutions have made them a trusted partner for optimizing warehouse operations and reducing material handling costs for clients in industries like distribution, manufacturing, and food processing.

The Future of Forklift Safety

As technology continues to advance, the future of forklift safety holds even greater promise. HCO Innovations and other industry leaders are continuously exploring innovative solutions to further enhance workplace safety. From the implementation of artificial intelligence (AI) for predictive maintenance to the development of autonomous forklifts, the future of forklift safety will be shaped by technology.

Companies like HCO Innovations are at the forefront of driving this innovation, utilizing their expertise to empower businesses with the latest technological advancements. By embracing these advancements and working with industry experts, companies can create safer work environments, protect their employees, and maximize operational efficiency.

The integration of technology into forklift fleet management is revolutionizing workplace safety. As companies like HCO Innovations leverage advanced software and cutting-edge technologies, the potential for accidents and injuries decreases dramatically. With the continuous evolution of technology, the future of forklift safety looks brighter than ever.

For more information on how HCO Innovations can help your business optimize its forklift fleet management and enhance workplace safety, visit their website at https://www.hcoinnovations.com/.