When it comes to warehouse operations, efficiency and productivity are key factors in ensuring a smooth operation. One area where optimization can greatly impact these factors is in forklift power management. Forklifts play a vital role in transporting goods within the warehouse, and their performance and energy usage can significantly impact overall operations.

The Need for Forklift Power Optimization

Managing the power consumption of forklifts is crucial for several reasons. Firstly, optimizing forklift power usage can improve the overall efficiency of warehouse operations. By using power more effectively, forklifts can operate for longer periods, reducing the need for frequent charging intervals.

Additionally, proper power management helps enhance the lifespan of forklift batteries. Overloading or undercharging the batteries can lead to premature wear and reduced battery longevity. Implementing power optimization strategies can help protect the batteries and extend their lifespan, reducing the need for frequent replacements.

Moreover, optimizing forklift power usage can also significantly reduce energy costs. Forklifts are known to be power-hungry machines, and inefficient power management can lead to unnecessary energy consumption and increased operational costs. By implementing power optimization techniques, companies can significantly reduce their electricity bills and improve their bottom line.

The Role of IoT in Forklift Power Optimization

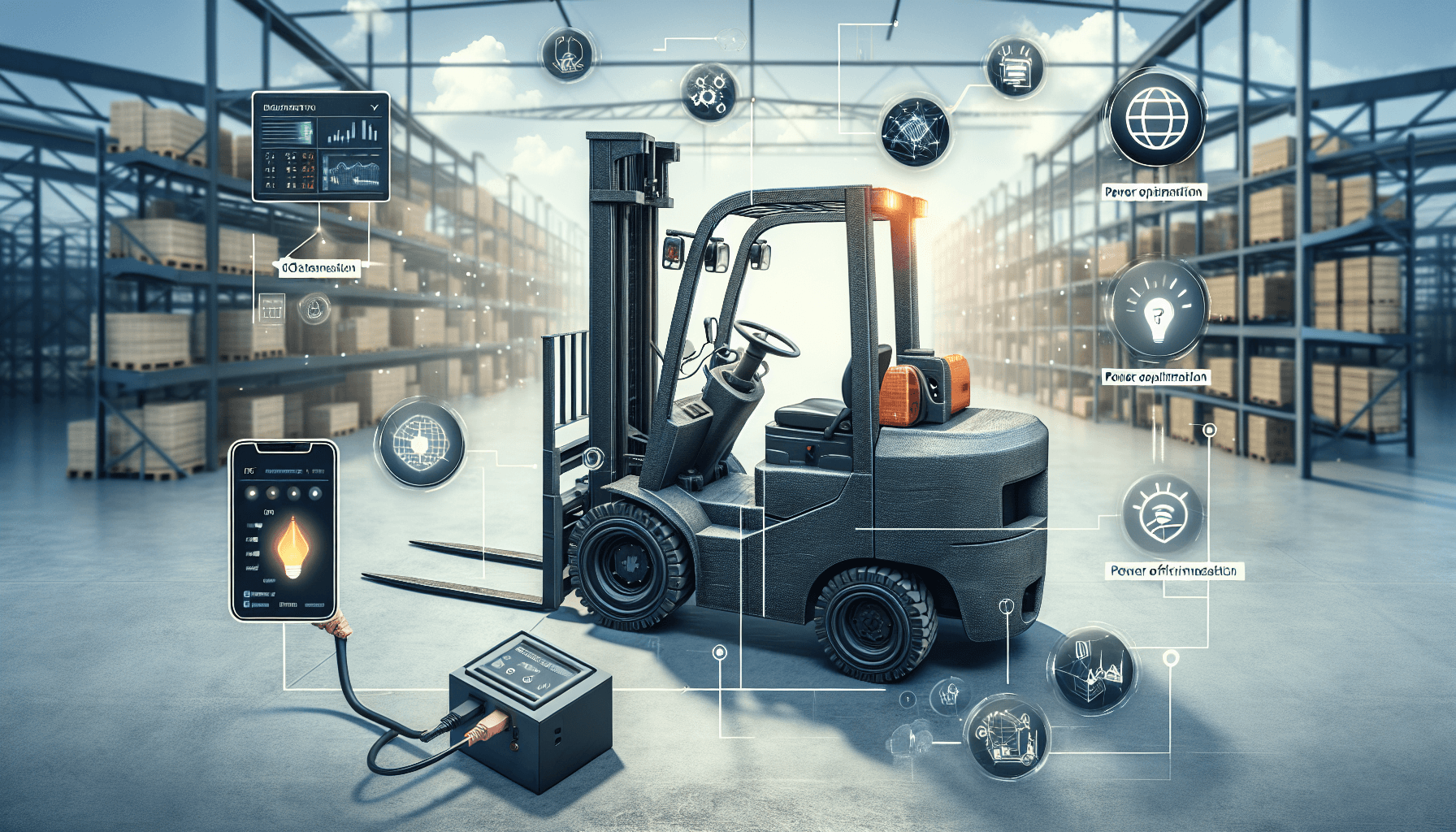

One technology that has revolutionized the forklift power optimization landscape is the Internet of Things (IoT). IoT refers to the network of connected devices that can collect, analyze, and transfer data over the internet. When it comes to forklifts, IoT has opened up a world of possibilities for optimizing their power consumption.

IoT-enabled forklifts can be equipped with sensors and monitoring devices that collect valuable data about their power usage, performance, and overall health. This data can then be transmitted in real-time to a central management system where it can be analyzed and used to make data-driven decisions.

By leveraging IoT technology, companies can gain valuable insights into their forklift fleet’s power consumption patterns. They can identify areas of inefficiency, such as excessive idling or aggressive acceleration, and develop strategies to address them. With IoT, companies can effectively track and monitor their forklifts’ power usage, implement preventive maintenance schedules, and optimize charging cycles.

One of the key advantages of IoT-based forklift power optimization is the ability to track and manage multiple forklifts simultaneously. With centralized control, managers can monitor the power usage of the entire forklift fleet from a single dashboard. This level of visibility allows for better decision-making, resource allocation, and performance tracking.

Another area where IoT plays a significant role in forklift power optimization is predictive maintenance. By analyzing the data collected from IoT-enabled forklifts, companies can identify signs of potential issues and schedule maintenance proactively. This proactive approach helps prevent unexpected breakdowns, minimizes downtime, and maximizes the efficiency of the fleet.

Furthermore, IoT-enabled forklifts can integrate with warehouse management systems (WMS) to further optimize operations. By sharing real-time data with the WMS, forklifts can be guided through optimized routes, reducing unnecessary travel and saving energy. This integration allows for better coordination between forklifts and other warehouse processes, leading to improved productivity and efficiency.

At HCO Innovations, we specialize in providing warehouse optimization solutions, including forklift power management. Our IoT-powered solutions are designed to enhance safety, productivity, and cost-effectiveness within warehouse operations. With our innovative technologies and expertise, we can help businesses take full control of their forklift fleet’s power consumption and optimize their operations for maximum efficiency.

If you’re interested in learning more about our forklift power management solutions, please visit our website for more information.

What is IoT and how does it relate to forklift power optimization?

IoT, or the Internet of Things, is a network of interconnected devices that communicate and exchange data with each other. In the context of forklift power optimization, IoT plays a crucial role by allowing for real-time monitoring and control of various factors that impact the power management of forklifts.

What are the benefits of using IoT for forklift power optimization?

Implementing IoT in forklift power optimization brings several benefits. It enables remote monitoring of battery health, usage patterns, and performance analytics, allowing for proactive maintenance and reducing downtime. It also facilitates the optimization of energy consumption, leading to cost savings and improved operational efficiency.

How does IoT optimize battery usage in forklifts?

IoT-based solutions use sensors and data analytics to monitor battery usage and health. This data is then utilized to implement smart charging algorithms, which optimize charging cycles based on usage patterns and battery condition. By ensuring efficient charging and avoiding overcharging, IoT helps extend battery life and usage per charge cycle.

Can IoT help in preventing battery-related accidents in forklifts?

Yes, IoT can contribute to preventing battery-related accidents in forklifts. By continuously monitoring battery voltage, temperature, and other crucial parameters, IoT solutions can send real-time alerts and warnings to operators and supervisors about potential battery issues. This early detection helps in taking preventive measures and avoiding hazardous situations.

Is it expensive to implement an IoT system for forklift power optimization?

The cost of implementing an IoT system for forklift power optimization varies depending on factors like the size of the fleet, complexity of deployment, and the specific IoT solution chosen. While there may be initial setup costs, the long-term benefits such as improved productivity and reduced maintenance expenses often outweigh the investment. Additionally, the price of IoT technology has been decreasing, making it more accessible and cost-effective over time.

What security measures are in place to protect IoT-enabled forklift power optimization systems?

IoT-enabled forklift power optimization systems typically incorporate several security measures. These may include encrypted communication protocols, secure authentication methods, and regular software updates to address any vulnerabilities. Additionally, access control features and user permissions ensure that only authorized personnel can access and modify the system, enhancing overall security.

Can IoT help in optimizing overall forklift fleet management?

Yes, IoT can play a significant role in optimizing overall forklift fleet management. By collecting and analyzing data from multiple forklifts, IoT systems can provide insights into usage patterns, maintenance needs, and performance metrics to facilitate better fleet planning and decision-making. This leads to optimized resource allocation, reduced costs, and improved operational efficiency.

What types of data can be collected and analyzed by IoT systems in forklift power optimization?

IoT systems in forklift power optimization can collect and analyze a wide range of data. This includes battery health, energy consumption, charging history, utilization patterns, location tracking, and even operator behavior. By analyzing this data, IoT technology enables businesses to make data-driven decisions and identify areas for improvement in forklift power management.

What are the potential future developments in IoT for forklift power optimization?

The field of IoT for forklift power optimization is constantly evolving. Potential future developments include advancements in machine learning algorithms for accurate predictive maintenance, integration of IoT with other automation technologies like autonomous forklifts, and the use of edge computing to enable faster and more efficient real-time data processing.

The Future of Connected Logistics: How IoT is Revolutionizing Supply Chain Management

The future of connected logistics is here, and it is revolutionizing supply chain management. With the advent of the Internet of Things (IoT), businesses are finding new ways to optimize their supply chains, improve operational efficiency, and reduce costs. As a leading management consulting firm specializing in warehouse optimization and forklift fleet management, HCO Innovations is at the forefront of this transformation.

What is the Internet of Things (IoT)?

The Internet of Things refers to the network of physical devices, vehicles, and other objects embedded with sensors, software, and connectivity that enables them to collect and exchange data. These devices, often referred to as "smart" devices, can communicate with each other and with centralized systems, allowing for real-time monitoring, analysis, and control.

IoT technology is revolutionizing supply chain management by providing businesses with unprecedented visibility and control over their operations. It enables them to track and monitor their inventory, assets, and equipment in real-time, allowing for greater efficiency, improved decision-making, and enhanced customer satisfaction.

The Impact of IoT on Supply Chain Management

The integration of IoT technology into supply chain management has numerous benefits for businesses across industries. Here are some key ways in which IoT is revolutionizing supply chain management:

- Real-Time Tracking and Monitoring: IoT devices such as sensors and RFID tags can be used to track and monitor inventory, assets, and shipments in real-time. This enables businesses to have complete visibility into their supply chain, allowing them to identify and resolve issues quickly and efficiently.

- Improved Operational Efficiency: IoT technology enables businesses to optimize their operations by automating processes and streamlining workflows. For example, sensors can be used to automatically trigger reorder notifications when inventory reaches a certain threshold, eliminating the need for manual inventory checks and reducing the risk of stockouts.

- Enhanced Inventory Management: IoT devices can provide real-time data on inventory levels, enabling businesses to have accurate and up-to-date information on stock availability. This helps in reducing excess inventory, avoiding stockouts, and improving overall inventory management.

- Predictive Maintenance: IoT devices can monitor the condition of equipment and machinery in real-time, detecting any anomalies or signs of potential failure. This allows for proactive maintenance, reducing equipment downtime and optimizing maintenance schedules.

- Supply Chain Visibility: IoT technology provides businesses with end-to-end visibility into their supply chain, from the manufacturing floor to the end consumer. This visibility allows for more accurate demand forecasting, better inventory planning, and improved responsiveness to customer demands.

HCO Innovations: Pioneering IoT in Supply Chain Management

As a leading management consulting firm, HCO Innovations is helping businesses leverage IoT technology to optimize their supply chain management and drive operational excellence. With our expertise in warehouse optimization and forklift fleet management, we understand the unique challenges businesses face in their supply chain operations.

At HCO Innovations, we work closely with our clients to evaluate their warehouse layout, conduct safety assessments, and provide turnkey maintenance solutions. We leverage advanced cost-tracking software and a collaborative "boots on the ground" approach to help businesses achieve significant cost reductions and operational efficiency.

Through the implementation of IoT technology, we help our clients achieve improved visibility and control over their supply chain. Our tailored solutions consistently deliver exceptional return on investment, making us a trusted partner for optimizing warehouse operations and reducing material handling costs.

By embracing the future of connected logistics, businesses can stay ahead of the competition, drive innovation, and unlock new opportunities for growth. With HCO Innovations as your partner, you can navigate the complexities of IoT implementation and unlock the full potential of your supply chain.

To learn more about how HCO Innovations can help you revolutionize your supply chain management with IoT, visit HCO Innovations.