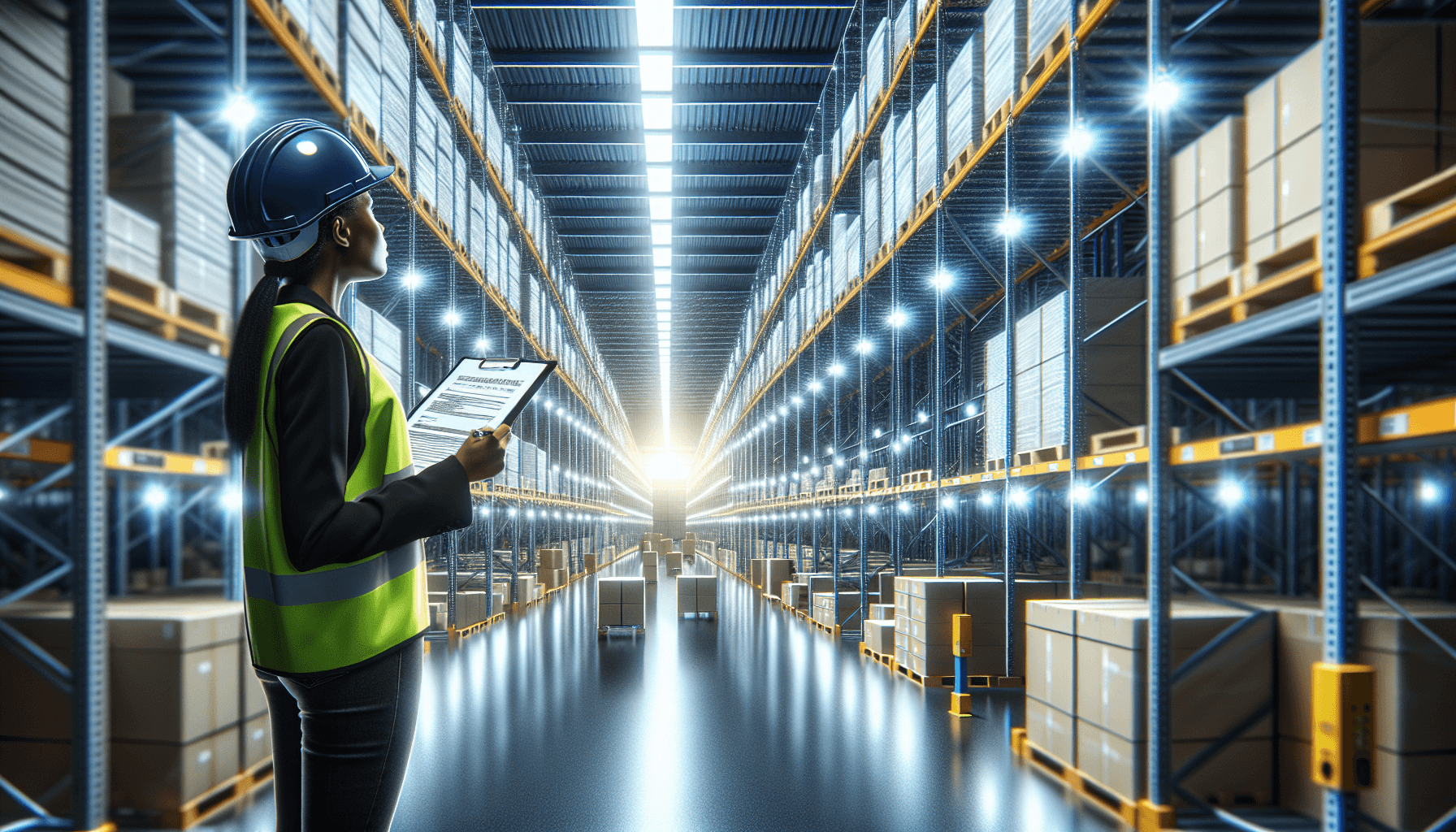

When it comes to ensuring the safety of employees and the smooth operation of a warehouse, there are several important factors to consider. One of these factors that often goes overlooked is the role of lighting in warehouse safety evaluations. Lighting plays a crucial role in creating a safe work environment and can significantly impact the overall efficiency and productivity of a warehouse.

The Importance of Adequate Lighting

Adequate lighting is essential in any workplace, but it becomes even more critical in a warehouse setting. Warehouses are typically large, with high ceilings and limited natural light. Without proper lighting, employees may struggle to see clearly, leading to an increased risk of accidents and errors.

There are several reasons why proper lighting is important in a warehouse:

- Enhanced Visibility: Good lighting ensures that employees can see clearly, allowing them to perform their tasks with precision and accuracy. It reduces the chances of misreading labels, mishandling products, or missing potential hazards.

- Reduced Eye Strain and Fatigue: Insufficient lighting can strain the eyes and cause fatigue, leading to decreased productivity and an increased risk of mistakes. By providing adequate lighting, employers can minimize eye strain and improve overall employee comfort.

- Improved Safety: Proper lighting helps prevent accidents by making potential hazards, such as obstacles, spills, or uneven surfaces, more visible. It promotes a safer work environment by allowing employees to navigate the warehouse more easily and avoid potential dangers.

- Accurate Inspections: Adequate lighting is vital for conducting thorough inspections of products, equipment, and the overall warehouse condition. It helps identify any defects, damages, or quality issues, ensuring that only safe and reliable items are distributed.

Factors to Consider in Lighting Evaluations

When evaluating the lighting in a warehouse, there are several factors to consider:

- Lighting Levels: The amount of light in a warehouse should be suitable for the tasks performed. Different areas may require different lighting levels. For example, picking and packing areas may need brighter lighting compared to storage areas.

- Uniformity: Lighting should be evenly distributed throughout the warehouse to minimize shadows and dark spots. Uneven lighting can create visual inconsistencies and make it difficult for employees to perceive depth, increasing the risk of accidents.

- Glare and Reflections: Glare and reflections from shiny surfaces can cause visual discomfort and make it challenging for employees to see clearly. Evaluating and minimizing glare is essential to improve visual comfort and prevent accidents.

- Color Temperature: The color temperature of lighting can affect the mood, perception, and visual clarity of employees. Cooler temperatures (bluer tones) can promote focus and alertness, while warmer temperatures (warmer tones) can create a more relaxed atmosphere.

- Energy Efficiency: Alongside safety considerations, it is important to consider energy-efficient lighting options to reduce electricity costs and minimize environmental impact.

By conducting regular lighting evaluations, employers can identify any areas that require improvement and take the necessary steps to enhance the lighting conditions in the warehouse. This can include replacing outdated lighting fixtures with more efficient and brighter options, repositioning lights to evenly distribute illumination, or implementing task-specific lighting solutions where necessary.

Choosing the Right Lighting Solutions

There are various lighting solutions available that can contribute to a safer and more efficient warehouse environment. These include:

- LED Lighting: LED lights are energy-efficient, long-lasting, and provide bright and consistent lighting. They are an excellent choice for warehouses due to their durability and low power consumption.

- Motion-Activated Lighting: Installing motion-activated lighting can help save energy by automatically turning off lights in areas that are not in use. This is especially useful in storage areas or lesser-used sections of the warehouse.

- Daylight Harvesting: Incorporating skylights or windows can maximize natural light during the daytime, reducing the need for artificial lighting and decreasing energy consumption.

- Emergency Lighting: Implementing emergency lighting systems with backup power sources ensures that employees can safely evacuate the warehouse during power outages or emergencies.

When choosing lighting solutions for a warehouse, it is essential to consider factors such as energy efficiency, maintenance requirements, and cost-effectiveness in the long run. Consulting with lighting experts or professionals can help determine the most suitable options for a specific warehouse layout and needs.

In conclusion, lighting plays a vital role in warehouse safety evaluations. Adequate lighting enhances visibility, reduces eye strain, improves safety, and allows for accurate inspections. Conducting regular lighting evaluations and choosing the right lighting solutions can help create a safer and more efficient work environment. Employers should prioritize proper lighting to ensure the well-being and productivity of their employees in the warehouse setting.

For more information on warehouse safety evaluations, visit HCO Innovations.