In warehouse operations, the maintenance of Material Handling Equipment (MHE) plays a crucial role in ensuring smooth and efficient operations. One key aspect of MHE maintenance that is often overlooked is the importance of proper lubrication. By implementing a comprehensive lubrication strategy, warehouse managers can optimize the performance, lifespan, and safety of their MHE.

The Benefits of Proper Lubrication

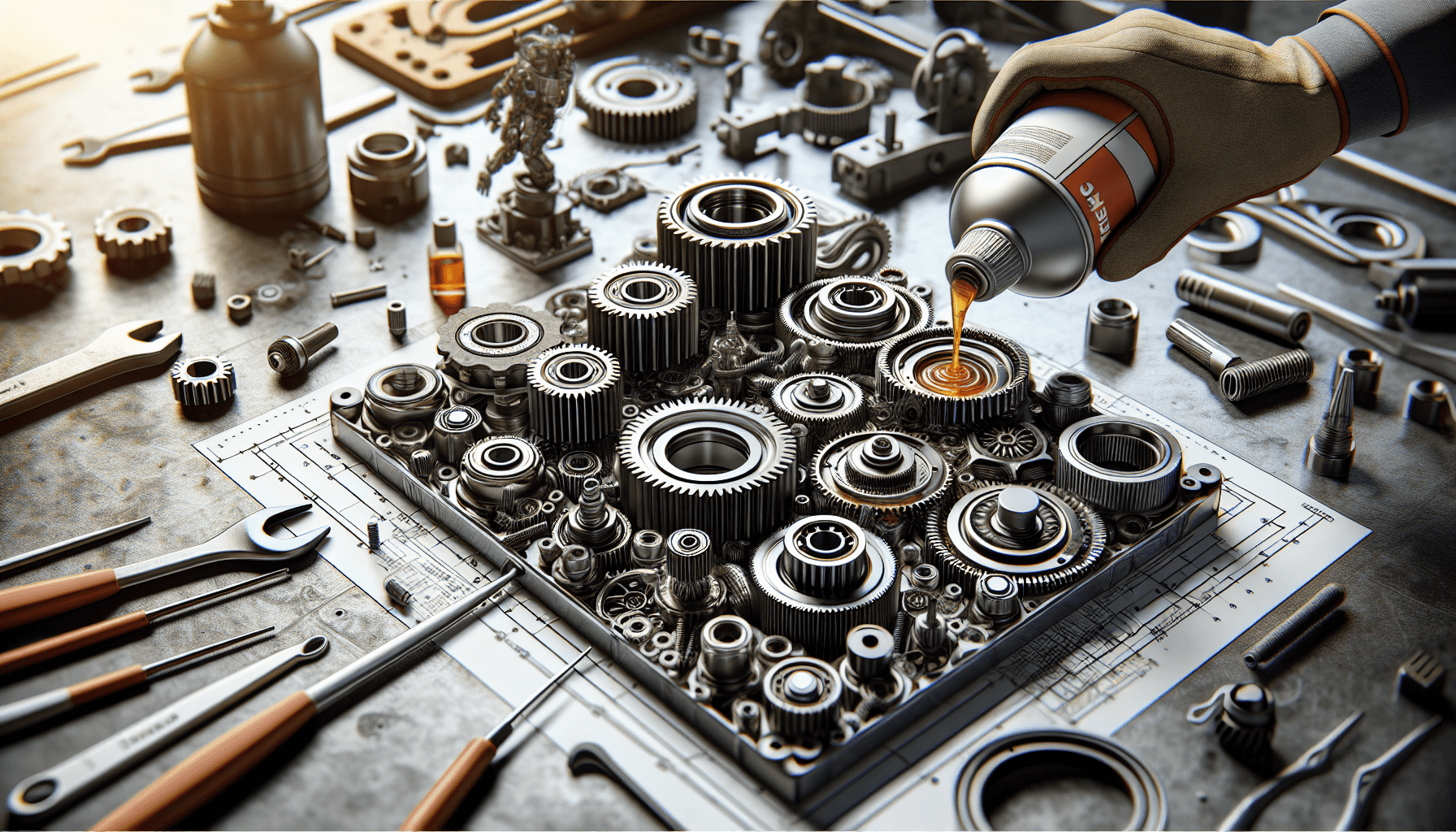

Lubrication is essential for the proper functioning of MHE components such as conveyors, lifts, forklifts, and automated systems. It reduces friction between moving parts, prevents wear and tear, and protects against corrosion. By maintaining proper lubrication, warehouse operators can benefit from:

- Enhanced Performance: Well-lubricated equipment operates smoothly, reducing downtime and increasing overall efficiency. MHE that runs smoothly allows for faster and more accurate material handling, leading to increased productivity.

- Extended Lifespan: Regular lubrication helps prevent excessive wear and tear on MHE components, prolonging their lifespan. This reduces the need for frequent repairs or replacements, resulting in long-term cost savings.

- Improved Safety: Lubrication reduces friction, minimizing the risk of overheating and potential accidents. Ensuring that all moving parts are properly lubricated helps maintain safe working conditions for warehouse personnel.

- Cost Savings: Proper lubrication can help avoid major breakdowns and expensive repairs. By investing in regular maintenance and lubrication, warehouse operators can save money in the long run.

It is important to note that different types of MHE require different lubrication methods. Warehouse managers should consult equipment manuals or manufacturer recommendations to determine the appropriate lubrication schedule and types of lubricants to use.

Developing an Effective Lubrication Strategy

Developing an effective lubrication strategy involves several key steps:

- Identify Critical Components: Identify the key MHE components that require regular lubrication. This may include bearings, chains, gears, and other moving parts. Focus on components that are subject to high loads, frequent use, or are prone to wear and tear.

- Determine Lubricant Types: Choose the appropriate lubricant types for each component. Factors to consider include temperature, load, speed, and environmental conditions. Utilize lubricants that are recommended by equipment manufacturers to ensure compatibility and optimal performance.

- Create a Lubrication Schedule: Develop a lubrication schedule based on the equipment manufacturer’s recommendations and operational requirements. Regularly inspect and track lubrication intervals to ensure consistent maintenance.

- Establish Proper Application Techniques: Train maintenance personnel on proper lubricant application techniques to ensure uniform coverage and prevent over or under-lubrication. Utilize tools such as grease guns, oil cans, and automatic lubrication systems for efficient and effective lubricant application.

- Maintain Documentation: Keep detailed records of lubrication activities, including dates, types of lubricants used, and the quantity applied. This documentation helps track maintenance history and facilitates troubleshooting in case of issues.

Regular inspection and monitoring are also essential in an effective lubrication strategy. Conduct routine checks to identify any signs of excessive wear, leaks, or inadequate lubrication. Promptly address any issues to prevent further damage and maintain optimal performance.

Additionally, consider implementing a Material Handling Equipment Management (MHEM) system to streamline maintenance processes. MHEM software can help warehouse managers track lubrication schedules, automate maintenance tasks, and generate detailed reports for analysis and decision-making. HCO Innovations offers a comprehensive MHEM solution that can greatly enhance warehouse operations. Learn more here.

In Conclusion

Proper lubrication is essential for maximizing the performance, lifespan, and safety of Material Handling Equipment in warehouse operations. By developing a comprehensive lubrication strategy, warehouse operators can optimize the efficiency and cost-effectiveness of their MHE maintenance practices. Don’t overlook the significance of lubrication in MHE maintenance – it can make a world of difference in your warehouse operations.