In the world of logistics and warehouse operations, transportation costs play a significant role in the overall efficiency and cost-effectiveness of the supply chain. Finding ways to reduce transportation costs can lead to substantial savings and increased profitability for businesses. One area where companies can make a significant impact on their transportation costs is through the effective management of Material Handling Equipment (MHE).

The Importance of MHE in Transportation

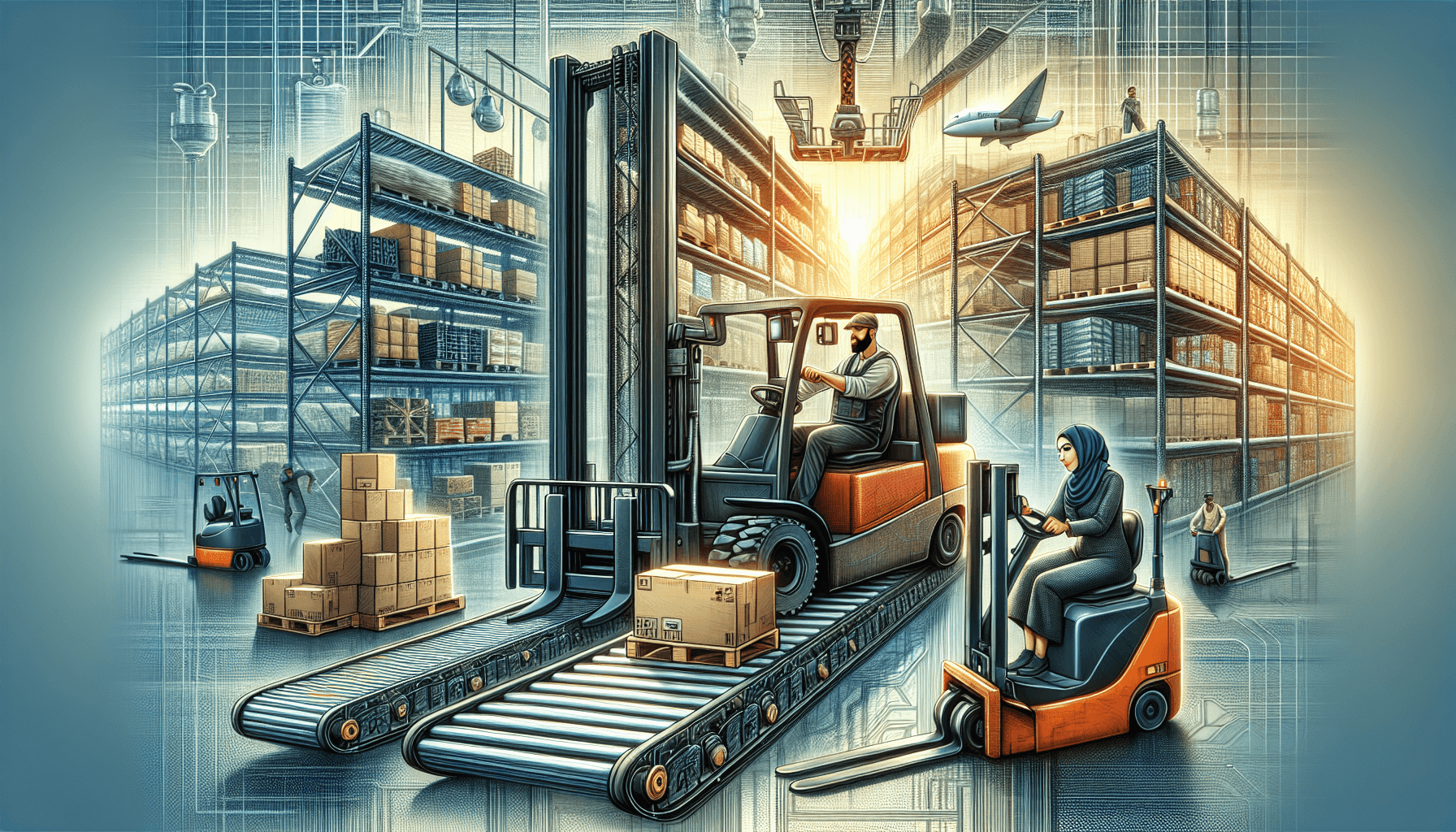

Material Handling Equipment refers to a wide range of tools, vehicles, and machinery used in the movement, storage, control, and protection of materials and products throughout various stages of the supply chain. These equipment include forklifts, pallet jacks, conveyor systems, automated guided vehicles (AGVs), and more. The efficient utilization and management of MHE can have a direct impact on transportation costs for several reasons.

- Optimized Loading and Unloading: By utilizing the right MHE and implementing efficient loading and unloading processes, companies can significantly reduce the time it takes to load and unload goods. This not only improves productivity but also reduces the waiting time for carriers, minimizing transportation costs.

- Improved Warehouse Layout: Properly organizing and optimizing the layout of a warehouse using MHE can streamline operations and reduce unnecessary movements. This results in faster picking and packing processes, reducing the overall handling time and ultimately lowering transportation costs.

- Efficient Inventory Management: Effective MHE management allows for accurate tracking and monitoring of inventory levels. By having real-time visibility into stock levels and location, companies can avoid stockouts, optimize order fulfillment, and reduce unnecessary expedited shipments, all of which contribute to lower transportation costs.

- Enhanced Safety Measures: By investing in reliable MHE and implementing proper safety protocols, companies can minimize accidents, damages, and product losses during transportation. This not only reduces costly insurance claims but also ensures that products are delivered in good condition, reducing the need for returns and replacements.

To achieve these benefits, companies should adopt a comprehensive approach to MHE management. This includes careful selection and maintenance of MHE, ongoing training for operators, and the implementation of advanced technology solutions that enable real-time monitoring and optimization of MHE operations.

At HCO Innovations, we understand the critical role that MHE plays in reducing transportation costs and improving overall warehouse efficiency. Our expertise lies in providing innovative warehouse optimization solutions, including MHE management systems, to help businesses unlock their full potential. Through our comprehensive services, we assist our clients in identifying the right MHE for their specific needs, optimizing their warehouse layout, implementing efficient inventory management practices, and establishing robust safety measures.

With our proven track record and industry-leading expertise, we are committed to helping businesses enhance safety, productivity, efficiency, and cost-effectiveness within their warehouse operations. By investing in MHE management solutions, businesses can reduce transportation costs, improve customer satisfaction, and gain a competitive advantage in today’s fast-paced logistics landscape.

If you’re interested in learning more about our Material Handling Equipment management solutions and how they can help reduce transportation costs, please click here to visit our website or contact us for a consultation.