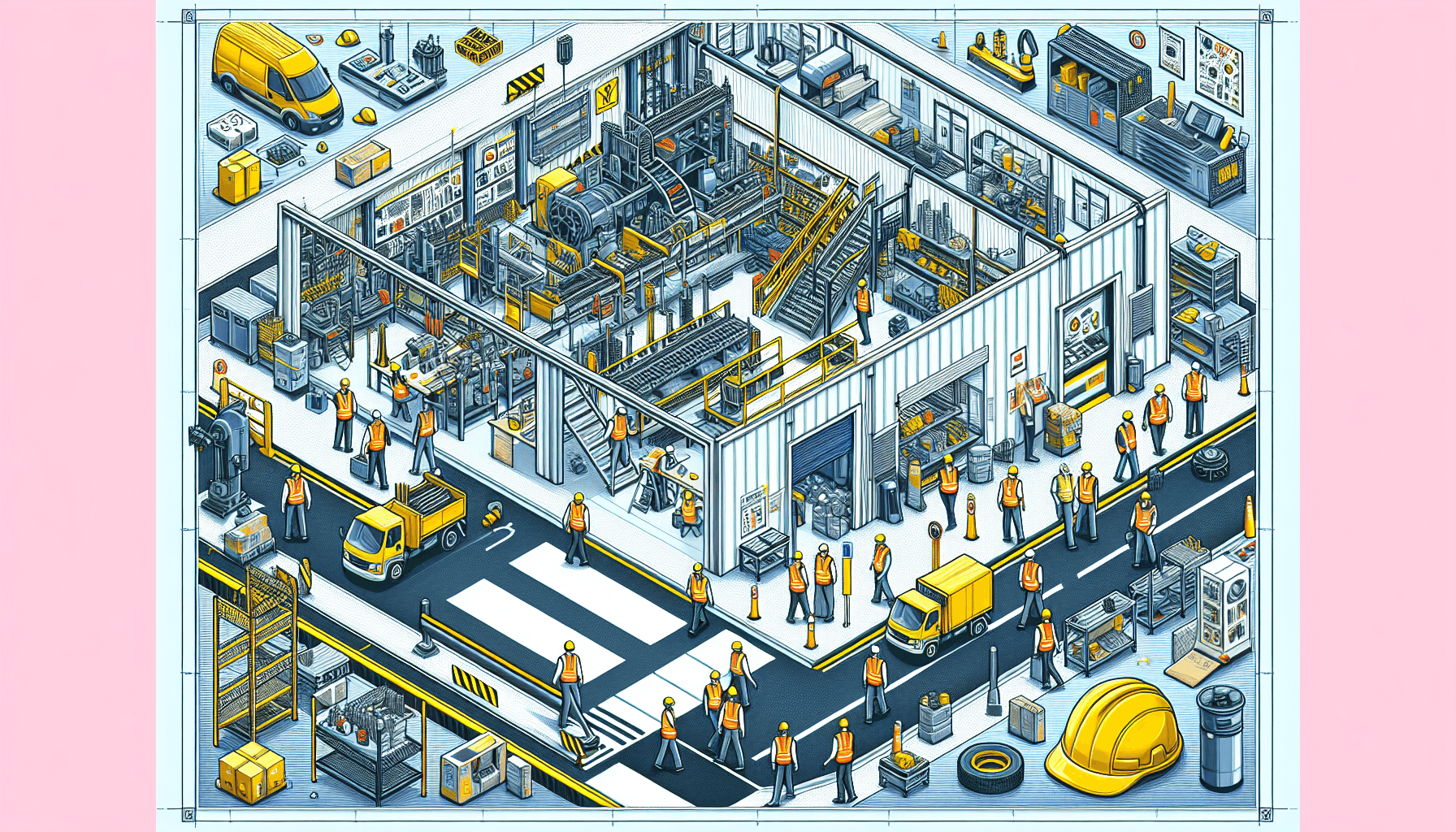

Warehouse pedestrian safety is of utmost importance in any warehouse operation. With the constant movement of forklifts, pallet jacks, and other machinery, it is necessary to prioritize the well-being of workers on foot. While implementing safety protocols and providing proper training are crucial steps, regular maintenance plays a vital role in ensuring a safe working environment. In this article, we will explore the significance of regular maintenance in warehouse pedestrian safety and how HCO Innovations can help optimize safety measures.

1. Equipment Reliability

Regular maintenance of warehouse equipment, including forklifts, conveyor systems, and automated storage and retrieval systems, ensures their reliability. Ensuring that the equipment is in proper working condition reduces the risk of malfunctions or breakdowns that could potentially harm pedestrians. Regular inspections, lubrication, and part replacements help identify and address any underlying issues before they escalate into safety hazards on the warehouse floor.

With HCO Innovations’ expertise in warehouse optimization solutions, warehouse managers can rely on their maintenance services to keep the equipment in top-notch condition. Their team of professionals is trained to identify potential safety risks and carry out preventive maintenance measures to keep the equipment functioning efficiently and safely.

2. Forklift Safety

Forklifts are widely used in warehouses for material handling purposes. They pose a significant risk to pedestrian safety due to their size, weight, and limited visibility. Regular maintenance of forklifts is crucial to ensure their safe operation. This includes regular inspections of brakes, tires, horns, lights, and other safety features.

An essential aspect of forklift safety is the implementation of a forklift pedestrian detection system. This innovative technology uses advanced sensors and cameras to detect the presence of pedestrians in the vicinity of forklifts and alerts the operators to take necessary precautions. HCO Innovations offers a state-of-the-art forklift pedestrian detection system that enhances safety by reducing the risk of collisions between forklifts and pedestrians.

3. Ergonomic Considerations

Regular maintenance extends beyond the equipment itself and also involves ensuring ergonomic considerations are met. Ergonomics plays a significant role in preventing work-related injuries and improving overall worker productivity. By regularly maintaining and optimizing workstations, such as adjusting the height of work surfaces, providing proper lighting, and implementing anti-fatigue flooring, the risk of musculoskeletal disorders can be minimized.

HCO Innovations offers a range of ergonomic solutions that can be tailored to the specific needs of a warehouse operation. Their ergonomic experts can conduct assessments and recommend ergonomic improvements, such as adding ergonomic workstations, implementing proper lifting techniques, and providing training on ergonomic best practices.

4. Training and Education

Regular maintenance provides an opportunity for training and education on safety procedures. As maintenance tasks are carried out, workers can be educated on safe equipment operation, hazard identification, and emergency response protocols. This ongoing training helps reinforce safety practices and creates a culture of safety in the warehouse.

HCO Innovations understands the importance of comprehensive training and education in ensuring warehouse pedestrian safety. They offer customizable training programs that cover a wide range of safety topics, including proper equipment operation, hazard recognition, and emergency evacuation procedures. Their training programs are designed to equip workers with the knowledge and skills necessary to maintain a safe and productive work environment.

Conclusion

Regular maintenance plays a crucial role in warehouse pedestrian safety. By ensuring equipment reliability, prioritizing forklift safety, addressing ergonomic considerations, and providing ongoing training and education, warehouses can create a safer working environment for all. HCO Innovations, with their expertise in warehouse optimization solutions, is dedicated to helping warehouses enhance safety, productivity, efficiency, and cost-effectiveness. Contact HCO Innovations today to learn more about how they can optimize your warehouse operations and improve pedestrian safety.