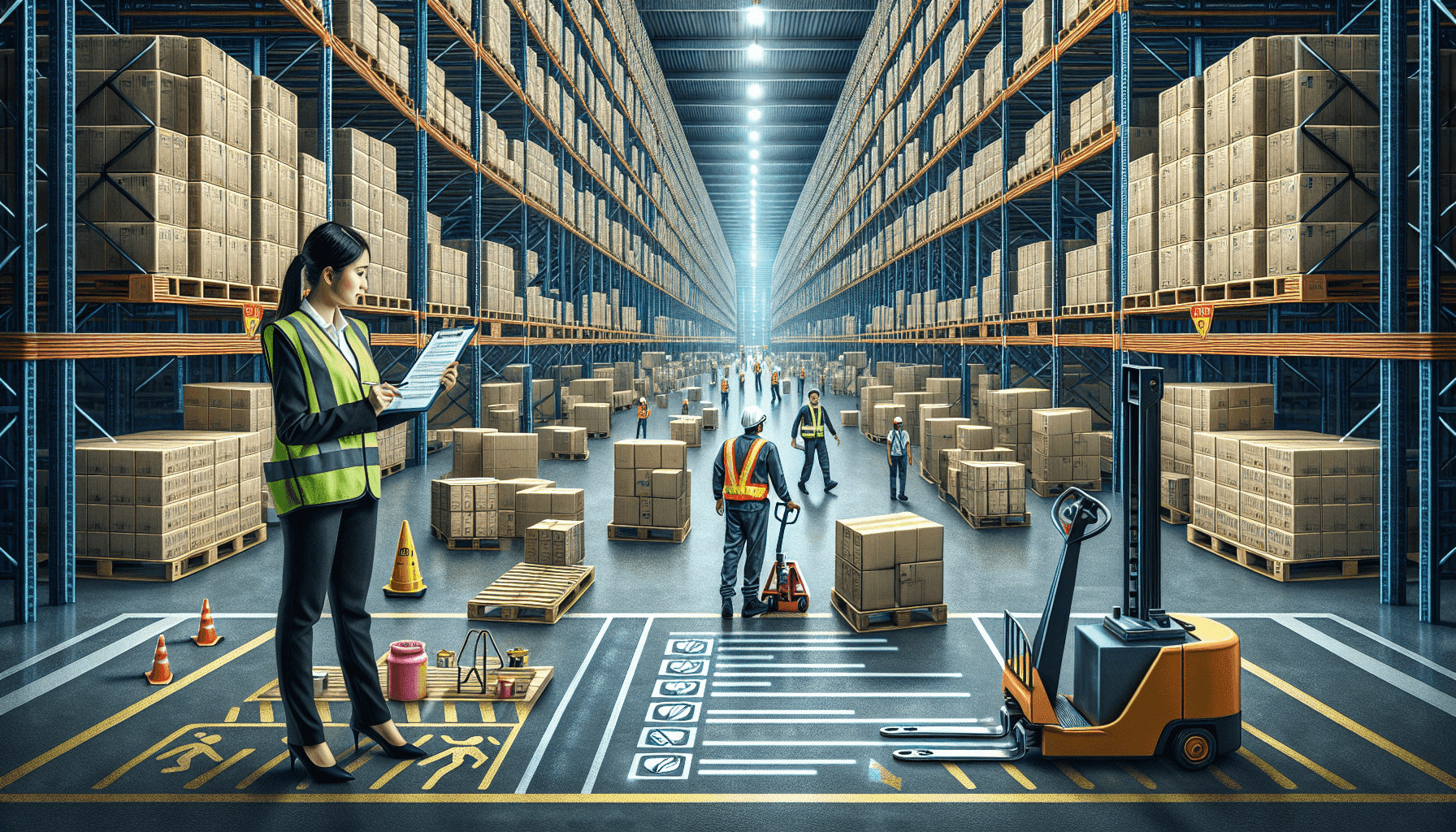

Warehouse operations can be a bustling environment with various moving parts and potential hazards. One critical aspect of maintaining a safe and efficient warehouse is ensuring pedestrian protection. With the use of heavy machinery such as forklifts, it is essential to implement measures that minimize the risk of accidents involving pedestrians. Safety audits play a vital role in identifying and addressing potential hazards in the warehouse environment.

The Importance of Safety Audits

Safety audits are systematic inspections that are conducted to assess compliance with safety standards, identify potential hazards, and develop corrective actions to mitigate risks. In the context of warehouse operations, safety audits are essential for enhancing pedestrian protection. They provide a comprehensive evaluation of the warehouse layout, equipment, processes, and procedures to identify areas of improvement.

One of the primary goals of safety audits is to proactively identify potential risks and hazards before they lead to accidents or injuries. By conducting regular safety audits, warehouse managers can detect and address issues related to pedestrian protection, such as inadequate signage, poor visibility, congested walkways, or insufficient training programs for both forklift operators and pedestrians. By identifying these concerns, corrective actions can be implemented to enhance safety and prevent accidents from occurring.

Safety audits also help ensure compliance with relevant occupational health and safety regulations. Adhering to these regulations is not only crucial for the well-being of the warehouse workforce but also protects the organization from potential legal liabilities. By conducting safety audits, warehouse operators can verify that their operations align with the required safety standards, reducing the risk of fines or penalties.

Key Components of a Safety Audit

A comprehensive safety audit should cover various aspects of warehouse operations to ensure holistic pedestrian protection. The following are key components that should be included in a safety audit:

- Layout and Design: The warehouse layout should prioritize the safety of pedestrians by ensuring clear pathways, designated pedestrian walkways, and proper separation between pedestrians and forklift traffic. The audit should evaluate the overall design of the warehouse to identify any potential bottlenecks or hazards.

- Training and Education: A crucial element of pedestrian protection is providing adequate training and education to both forklift operators and pedestrians. The audit should assess the availability and effectiveness of training programs, ensuring that employees are equipped with the knowledge and skills necessary to navigate safely in the warehouse environment.

- Visibility and Signage: Clear visibility is essential for minimizing the risk of accidents involving pedestrians and forklifts. The safety audit should evaluate the visibility within the warehouse, including lighting conditions, signage, and reflective markings. It should identify any areas where visibility could be improved to enhance pedestrian safety.

- Equipment Maintenance: Well-maintained equipment is critical for ensuring the safety of pedestrians in the warehouse. The safety audit should assess the maintenance procedures for forklifts and other machinery, checking for any potential issues that could pose a risk to pedestrians.

- Emergency Preparedness: In the event of an emergency, such as a fire or evacuation, it is important to have proper protocols in place to protect the safety of all individuals in the warehouse. The safety audit should evaluate the effectiveness of emergency plans and procedures, including evacuation routes and the availability of emergency equipment.

By conducting a thorough safety audit that addresses these key components, warehouse operators can identify areas for improvement and implement necessary changes to enhance pedestrian protection.

Leveraging Technology for Enhanced Pedestrian Protection

In addition to safety audits, advancements in technology have made it possible to enhance pedestrian protection in warehouses further. One such technology is the Forklift Pedestrian Detection System provided by HCO Innovations. This innovative system utilizes sensors and advanced algorithms to detect the presence of pedestrians near forklifts and issues warnings to both the forklift operator and the pedestrians.

The Forklift Pedestrian Detection System acts as an additional layer of protection by providing real-time alerts to prevent potential collisions between forklifts and pedestrians. By installing this system, warehouse operators can significantly reduce the risk of accidents and injuries, further enhancing the safety of their operations.

Conclusion

Ensuring pedestrian protection is a critical aspect of warehouse operations. Safety audits play a vital role in identifying potential hazards, assessing compliance with safety standards, and implementing corrective actions to enhance pedestrian safety. By conducting regular safety audits, warehouse operators can proactively identify and address areas for improvement, ultimately reducing the risk of accidents and injuries.

Additionally, leveraging technology like the Forklift Pedestrian Detection System can provide an extra layer of protection and enhance pedestrian safety in the warehouse environment. By combining safety audits with technological advancements, warehouse operators can create a safer and more efficient working environment for both pedestrians and forklift operators.

Click here to learn more about how HCO Innovations can assist in enhancing pedestrian protection in your warehouse operations.

What is a safety audit and why is it important for warehouse pedestrian protection?

A safety audit is a systematic evaluation of a workplace's safety practices and procedures. It involves identifying potential hazards, assessing safety measures, and recommending improvements. Safety audits play a crucial role in enhancing warehouse pedestrian protection by identifying areas of risk, ensuring compliance with safety regulations, and implementing measures to prevent accidents and injuries.

When should I conduct a safety audit in my warehouse?

It is recommended to conduct regular safety audits in your warehouse to maintain a safe working environment. Ideally, safety audits should be performed annually, but they may also be conducted more frequently if there are changes in operations, equipment, or safety regulations. It is important to be proactive and prioritize safety, so conducting safety audits regularly is crucial.

What are the common areas of concern in warehouse pedestrian safety?

Common areas of concern in warehouse pedestrian safety include proper signage and markings, traffic flow management, clear pedestrian walkways, visibility of pedestrians and vehicles, use of personal protective equipment, and training programs for employees. Addressing these areas helps minimize the risk of accidents and injuries to pedestrians in a warehouse environment.

How can safety audits help prevent pedestrian accidents in warehouses?

Safety audits help prevent pedestrian accidents in warehouses by identifying potential hazards and implementing preventive measures. Audits can pinpoint areas that need improvement, such as installing barriers or guardrails, enhancing visibility through proper lighting, implementing traffic control systems, providing training on pedestrian safety, and ensuring compliance with safety standards and regulations.

Who should conduct safety audits in a warehouse?

Safety audits in a warehouse can be conducted by internal safety teams or external professionals specializing in safety audits. If conducted internally, the responsible team should have adequate knowledge and training in safety assessment. When outsourcing, it is important to choose reputable auditors with experience in warehouse safety evaluations.

Can safety audits help reduce the costs associated with accidents?

Yes, safety audits can help reduce the costs associated with accidents. By identifying and addressing potential hazards, safety audits can prevent accidents and injuries from occurring in the first place. This helps to minimize direct costs such as medical expenses and workers' compensation claims, as well as indirect costs including lost productivity, damage to equipment or inventory, and potential legal fees.

What should I do with the findings from a safety audit?

Once you have the findings from a safety audit, it is important to take immediate action to address any identified issues. Create an action plan that outlines the necessary steps to rectify deficiencies, improve safety measures, and mitigate risks. Assign responsible individuals or teams to implement the plan and establish a follow-up process to ensure the changes are effective in enhancing warehouse pedestrian protection.

Creating a Culture of Safety in Warehouses: Best Practices for Effective Employee Training

Warehouses are dynamic environments with numerous potential hazards, making it crucial for organizations to prioritize employee safety. By fostering a culture of safety and providing effective training, companies can significantly reduce the risk of accidents and injuries in the workplace. In this article, we will explore the best practices for creating a culture of safety in warehouses and how HCO Innovations can assist you in this endeavor.

Prioritizing Safety

Before diving into best practices for employee training, it is important for organizations to understand why safety should be a top priority. Beyond the obvious ethical and legal obligations to provide a safe working environment, prioritizing safety can yield numerous benefits for businesses:

- Reduced Costs: Accidents and injuries can result in significant financial losses due to medical expenses, worker compensation claims, and increased insurance premiums. Implementing safety measures can prevent these costs.

- Improved Productivity: When employees feel safe and have confidence in their surroundings, they are more likely to focus on their tasks, resulting in increased productivity and efficiency.

- Enhanced Reputation: Demonstrating a commitment to employee safety can enhance your organization's reputation as a responsible and caring employer, attracting top talent and fostering positive relationships with clients and partners.

- Legal Compliance: By implementing proper safety practices, you ensure compliance with local and federal regulations, reducing the risk of penalties and legal issues.

Now that we understand the importance of safety in warehouses, let's explore the best practices for effective employee training:

1. Develop a Comprehensive Training Program

To create a culture of safety, it is essential to develop a comprehensive training program that covers all aspects of warehouse operations. This training program should include:

- General Safety Procedures: Train employees on basic safety procedures, such as proper lifting techniques, emergency protocols, and the use of personal protective equipment (PPE).

- Equipment Specific Training: Provide specialized training on the safe operation of forklifts, pallet jacks, and other equipment commonly used in warehouses. HCO Innovations offers forklift fleet management services and can assist in developing tailored training programs.

- Hazard Recognition and Control: Educate employees on how to identify potential hazards, such as slippery surfaces, unstable storage racks, or exposed wiring, and provide them with strategies to prevent accidents.

- Fire Safety: Ensure that employees are trained on proper fire prevention, evacuation plans, and the use of fire extinguishers.

- Health and Wellness: Promote a culture of wellness by providing training on ergonomics, proper nutrition, and the importance of regular exercise.

By designing a comprehensive training program, you can ensure that employees are equipped with the knowledge and skills to work safely in any warehouse environment.

2. Tailor Training to Individual Roles and Responsibilities

Every employee in a warehouse has unique roles and responsibilities. It is important to tailor the safety training to specific job functions to ensure maximum effectiveness. Consider the following approaches:

- Task-Specific Training: Provide training that is specific to the tasks that employees are expected to carry out. For example, employees involved in loading and unloading trucks may require specialized training on proper lifting techniques and safe loading procedures.

- Supervisor Training: Train supervisors and managers on their responsibilities in promoting and enforcing safety protocols. This includes conducting regular safety inspections, addressing safety concerns, and promoting a culture of safety through leadership.

- Maintenance Training: Ensure that maintenance personnel receive training on inspecting and maintaining equipment to prevent breakdowns and avoid potential safety hazards.

HCO Innovations specializes in warehouse optimization and can help in identifying specific training needs based on your organization's unique requirements.

3. Regularly Evaluate and Update Training

Creating a culture of safety is an ongoing process. It is important to regularly evaluate and update your training program to ensure its relevance and effectiveness. Consider the following steps:

- Training Assessments: Regularly assess the effectiveness of the training program by conducting quizzes, surveys, or practical evaluations. Use the feedback to identify areas that require improvement.

- Continuing Education: Provide opportunities for employees to further enhance their safety knowledge through workshops, seminars, or online training courses. Encourage ongoing learning and professional development.

- Stay Updated on Regulations: Keep yourself informed about the latest safety regulations and industry best practices to ensure that your training program remains compliant and up to date.

HCO Innovations stays up to date with the latest trends and regulations in warehouse optimization and can provide you with the necessary resources to keep your training program effective and compliant.

Creating a culture of safety requires a proactive approach and a commitment to continuous improvement. By implementing a comprehensive training program, tailored to individual roles and responsibilities, and regularly evaluating and updating the program, you can ensure the safety of your employees and the success of your warehouse operations.

At HCO Innovations, we understand the importance of safety in the warehouse environment. With our expertise in warehouse optimization and forklift fleet management, we can help you create a culture of safety through our comprehensive training programs and cost-saving solutions. Visit HCO Innovations to learn more about our services and how we can partner with you to reduce material handling costs and optimize your warehouse operations.