In today’s fast-paced and competitive business environment, companies are constantly seeking ways to optimize their warehouse operations and reduce costs. One area that often presents significant cost challenges is material handling equipment (MHE). However, with the advancements in technology, there are now innovative solutions available that can help businesses effectively manage and reduce MHE costs.

The Impact of MHE Costs

Material handling equipment plays a crucial role in warehouse operations, as it is responsible for the movement, storage, and transportation of goods and materials. While essential, the costs associated with MHE can add up quickly and negatively impact a company’s bottom line.

Some common costs associated with MHE include:

- Equipment purchase or lease

- Maintenance and repairs

- Operator training and wages

- Energy consumption

- Productivity losses due to equipment downtime

All these costs can significantly impact a company’s profitability and competitiveness. Therefore, finding ways to reduce MHE costs is a key concern for warehouse managers and supply chain professionals.

The Role of Technology

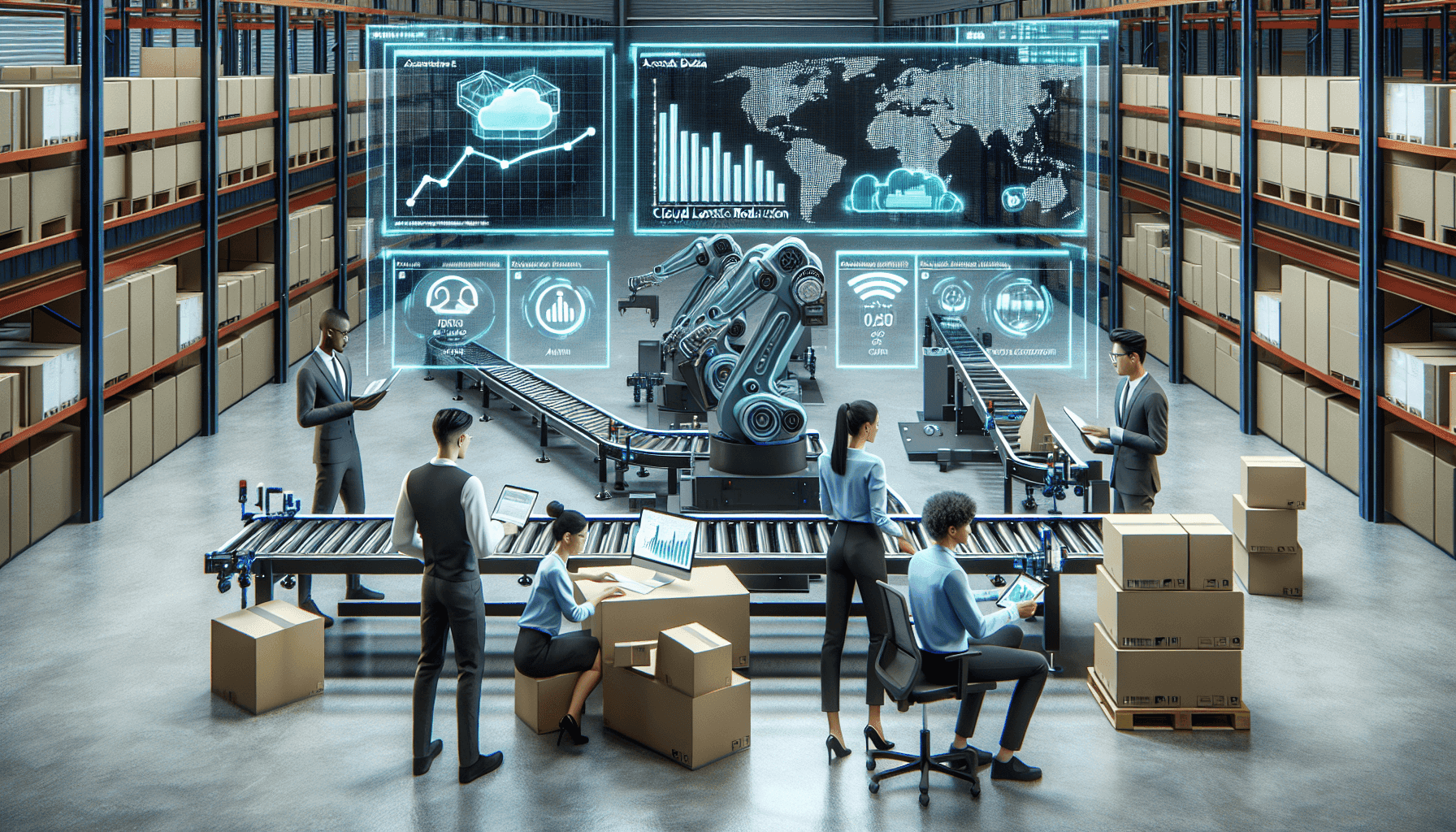

Technology has been a game-changer in the field of warehouse optimization. With the advent of smart technologies and data-driven solutions, businesses can now leverage advanced tools to enhance safety, productivity, efficiency, and cost-effectiveness within their warehouse operations.

One area where technology has made significant strides is in the management of material handling equipment. By adopting innovative solutions, businesses can effectively track and optimize their MHE usage, thereby reducing costs.

Here are some ways in which technology can help reduce MHE costs:

- Real-time Asset Tracking: Advanced tracking technologies such as RFID (Radio Frequency Identification) and GPS (Global Positioning System) allow businesses to monitor the location and movement of their MHE in real-time. By having accurate visibility, warehouse managers can optimize equipment utilization, prevent loss or theft, and schedule maintenance effectively.

- Predictive Maintenance: Technology-enabled predictive maintenance solutions use data analytics and machine learning algorithms to identify potential equipment failures before they occur. By having insights into the health of their MHE, businesses can proactively schedule maintenance, reduce unplanned downtime, and avoid costly repairs.

- Automation: Automated technologies such as conveyor systems, robotic picking and sorting systems, and automated guided vehicles (AGVs) can help streamline the movement of goods in the warehouse. By minimizing manual handling and maximizing efficiency, businesses can optimize their MHE usage and reduce labor costs.

- Energy Management: Energy-efficient technologies and smart energy management systems can help businesses reduce their energy consumption related to MHE operations. By optimizing equipment usage, implementing energy-saving measures, and monitoring energy consumption, companies can save on utility costs and contribute to sustainability efforts.

- Data Analytics: By harnessing the power of data, businesses can gain insights into their MHE usage patterns, identify inefficiencies, and make data-driven decisions to optimize their operations. Advanced analytics platforms and warehouse management systems enable businesses to monitor key performance indicators (KPIs), identify areas for improvement, and streamline their MHE processes.

HCO Innovations, a prominent provider of warehouse optimization solutions, offers comprehensive MHE management services. Their innovative solutions leverage technology to help businesses effectively manage their material handling equipment and reduce costs. Whether it’s real-time asset tracking, predictive maintenance, automation, energy management, or data analytics, HCO Innovations provides customized solutions tailored to the unique needs of each business.

By implementing technology-driven MHE optimization solutions, businesses can not only reduce costs but also improve operational efficiency and gain a competitive edge in the market. With the right blend of technology, expertise, and strategic partnerships, companies can unlock the full potential of their warehouse operations and create a more sustainable and profitable future.