Warehouse collaboration plays a crucial role in ensuring the smooth and efficient operation of any warehouse. When employees work together effectively and efficiently, it leads to improved productivity, increased customer satisfaction, and ultimately, higher profitability for the business.

What is Warehouse Collaboration?

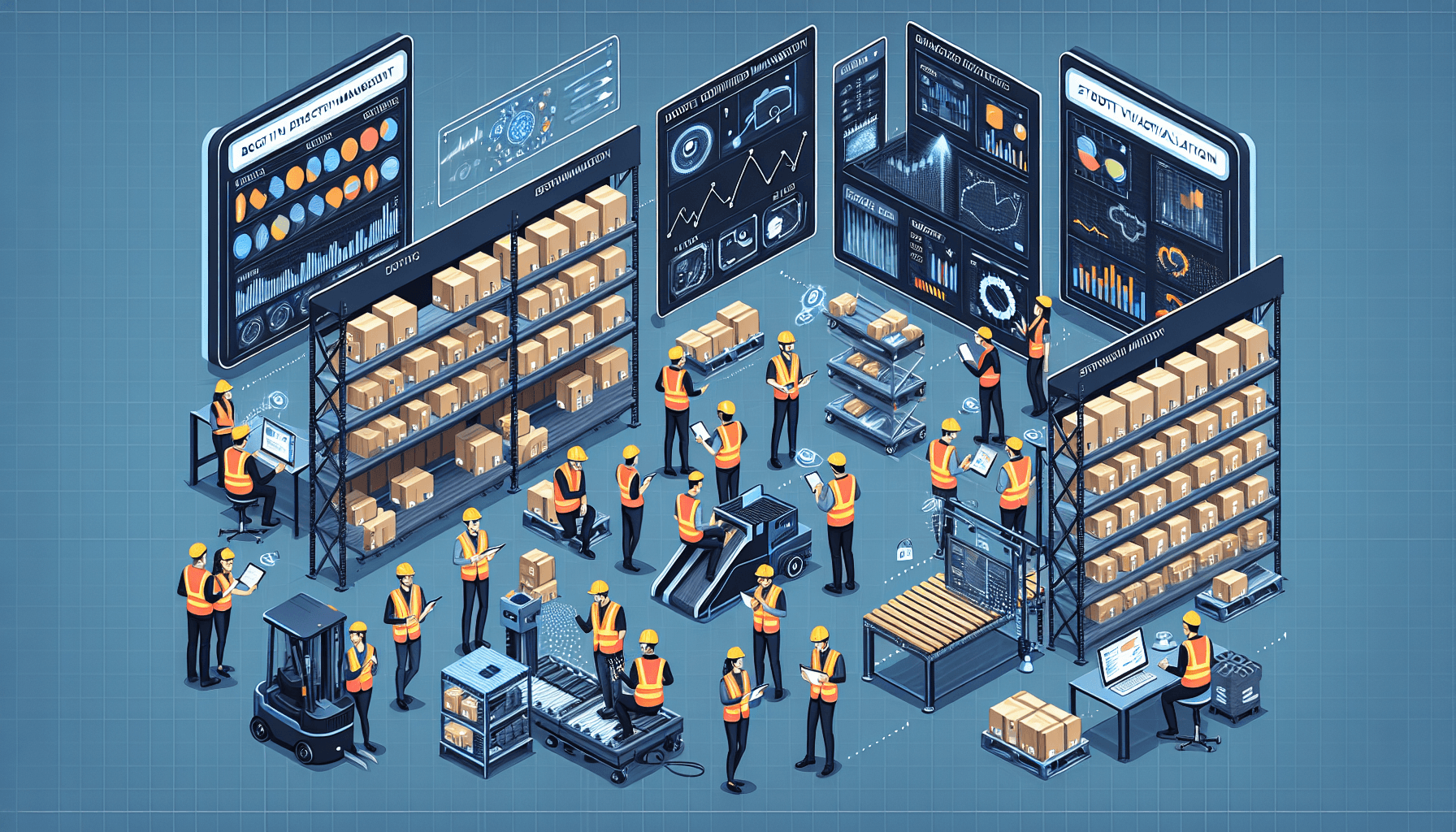

Warehouse collaboration refers to the coordinated efforts of warehouse staff, managers, and other stakeholders to work towards common goals and objectives. This collaboration involves effective communication, sharing of information, and efficient utilization of resources to optimize warehouse operations.

One of the key technologies that enable and enhance warehouse collaboration is the Warehouse Management System (WMS). A WMS is a software solution that helps businesses manage and control various aspects of warehouse operations, including inventory management, order fulfillment, and resource optimization.

The Role of WMS in Enhancing Warehouse Collaboration

A WMS plays a critical role in improving warehouse collaboration by providing real-time visibility and centralizing information. Here’s how:

- Real-time Inventory Visibility: A WMS allows warehouse staff to have up-to-date visibility of inventory levels, locations, and movements. This real-time information helps employees collaborate more effectively by enabling them to make informed decisions about stock availability, order status, and replenishment needs. This visibility also allows different teams, such as sales and customer service, to provide accurate information to customers regarding order status and availability.

- Efficient Order Fulfillment: With a WMS, warehouse collaboration is enhanced through streamlined order fulfillment processes. The system provides intelligent picking algorithms, which optimize the sequencing of picks and suggest the most efficient routes for the pickers. This not only improves productivity but also reduces errors and minimizes travel time, enabling employees to collaborate effectively and fulfill orders accurately and on time.

- Resource Optimization: A WMS helps in optimizing warehouse resources, such as labor and equipment, through task assignment and scheduling. The system analyzes factors like workload, capacity, and employee skill sets to assign tasks to the right personnel at the right time. This ensures that resources are utilized efficiently, leading to improved collaboration and overall warehouse performance.

- Collaborative Decision Making: The centralized nature of a WMS allows all team members to access and share information from a single source. This promotes collaboration and facilitates better decision-making processes. Warehouse managers and staff can quickly access critical data, such as demand forecasts, stock levels, and performance metrics, to make informed decisions together. This collaborative approach leads to better resource allocation, improved operational efficiency, and increased warehouse productivity.

Warehouse collaboration is further enhanced by the mobile capabilities of modern WMS. With mobile devices, warehouse staff can access real-time information, communicate with team members, and update task statuses on the go. This mobility fosters quick and direct collaboration, allowing employees to work together seamlessly across different areas of the warehouse.

Additionally, a WMS can integrate with other systems and technologies, such as barcode scanners, RFID systems, and automated material handling equipment, further improving warehouse collaboration. These integrations enable real-time data exchange and automation of certain tasks, reducing manual errors and enhancing collaboration among different teams and systems.

In conclusion, warehouse collaboration is essential for optimizing warehouse operations and achieving business success. A Warehouse Management System (WMS) plays a crucial role in enhancing collaboration by providing real-time visibility, streamlining order fulfillment, optimizing resources, and enabling collaborative decision-making. With the advancements in WMS technology, warehouses can foster a culture of collaboration, making their operations more efficient, productive, and cost-effective.

To learn more about how HCO Innovations can help enhance your warehouse collaboration with our advanced WMS solutions, please visit our website.