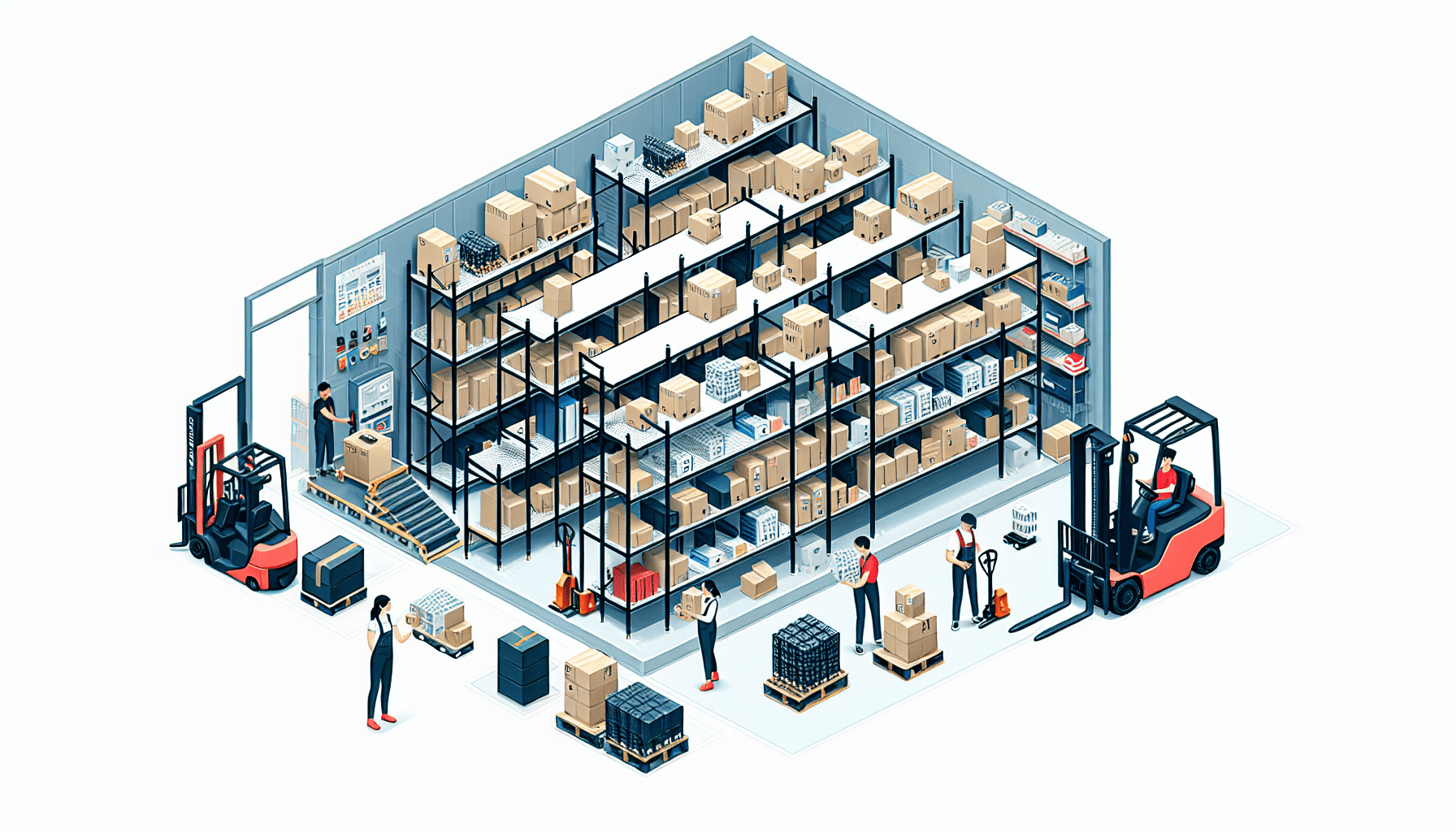

When it comes to running a warehouse, space is a precious commodity. Maximizing the use of available space is crucial for improving productivity and efficiency. However, many warehouses often face the challenge of limited space, making it essential to find effective warehouse layout solutions for small spaces.

Importance of Optimizing Warehouse Layout

An optimized warehouse layout is the key to achieving maximum productivity and efficiency. By effectively utilizing every inch of available space, warehouse operations can be streamlined, reducing unnecessary movement, saving time, and minimizing errors.

Here are some key reasons why optimizing warehouse layout is critical:

- Enhances safety: An optimized layout ensures clear pathways, proper signage, and designated areas for equipment and personnel, reducing the likelihood of accidents and improving overall safety within the warehouse.

- Increases productivity: A well-planned layout minimizes travel time, reduces idle time, and ensures easy access to high-demand items, enabling workers to complete tasks quickly and efficiently.

- Improves workflow: Optimizing the warehouse layout allows for a logical flow of materials, ensuring smooth movement from receiving to storage, picking, packing, and shipping, optimizing the overall workflow.

- Optimizes stock storage: By utilizing smart storage solutions and making the best use of vertical space, warehouses can maximize their storage capacity, accommodating more stock within a limited area.

- Reduces costs: An optimized warehouse layout eliminates wasted space, which can lead to decreased operating costs, shorter order fulfillment times, and minimized labor expenses.

Warehouse Layout Solutions for Small Spaces

When dealing with limited warehouse space, creative and strategic solutions are essential. Here are some effective warehouse layout solutions for small spaces:

1. Vertical Storage

One of the most efficient ways to make the most of a small warehouse space is by utilizing vertical storage options. This involves utilizing high-quality shelving units or racks that can extend upwards, taking advantage of the height of the warehouse. By using mezzanine floors or installing vertical carousels, businesses can effectively store more inventory and maintain easy accessibility.

2. Modular Shelving

Modular shelving systems provide businesses with flexibility in organizing their inventory. These systems consist of adjustable and configurable shelves that can be easily modified to accommodate different product sizes. By utilizing modular shelving, businesses can optimize space by adjusting the shelf heights based on the items being stored.

3. Narrow Aisle Layout

A narrow aisle layout is an effective solution for maximizing storage in small warehouses. By reducing aisle widths and utilizing specialized equipment such as narrow aisle forklifts or automated guided vehicles (AGVs), businesses can achieve significant space savings. This layout allows for dense storage without compromising accessibility.

4. Mezzanine Floors

Mezzanine floors provide an additional level of storage space within a warehouse. These temporary or semi-permanent structures can be easily installed without requiring structural changes to the building. Mezzanine floors are particularly useful for storing smaller items and can be designed to accommodate different weight loads as per the business needs.

5. Cross-Docking

Cross-docking is a strategy where incoming materials or products are immediately transferred from the receiving area to the outbound shipping area, bypassing the need for storage. This technique minimizes the need for large storage areas and allows for a more streamlined and efficient flow of goods.

6. Warehouse Management System

Implementing a Warehouse Management System (WMS) can significantly improve warehouse efficiency, even in small spaces. A WMS helps with inventory control, optimizing picking routes, and streamlining operational processes. By automating tasks and providing real-time visibility, a WMS maximizes space utilization and improves overall productivity.

Every warehouse is unique, and the layout solutions for small spaces may vary depending on the specific requirements and challenges faced by the business. It is essential to consult with warehouse optimization experts like HCO Innovations, who specialize in providing customized and innovative solutions for warehouse layout and design.

Get in touch with HCO Innovations to learn more about how their warehouse optimization solutions can transform your small space into an efficient and productive warehouse.

Optimizing a warehouse layout for small spaces requires careful planning and consideration. By implementing the right solutions, businesses can overcome space constraints and achieve optimal efficiency within their warehouse operations.